For infrastructure, machinery, and produced goods subjected to mechanical stress, chemical exposure, and hostile surroundings, industrial coatings are the first line of defence that is vital. Beyond appearance, these coatings are essential for maintaining the lifetime, safety, and performance of assets in sectors including oil and gas, automotive, marine, construction, and manufacturing.

However the actual efficiency of any coating system depends on its application and maintenance as much as its formulation. Achieving the best protection and performance depends on proper surface preparation, appropriate coatings application methods, and adherence to curing guidelines. Likewise, regular maintenance and inspection help coatings last much longer, so lowering long-term repair costs and downtime. Here are some of the best practices, challenges, and modern developments in the application and maintenance of industrial coatings.

What are the Application Methods Of Industrial Coatings?

Industrial coating processes are very important in safeguarding, improving and prolonging the service life of both manufactured goods and materials in all sorts of industries. The following are key methods of applying protective and decorative coatings:

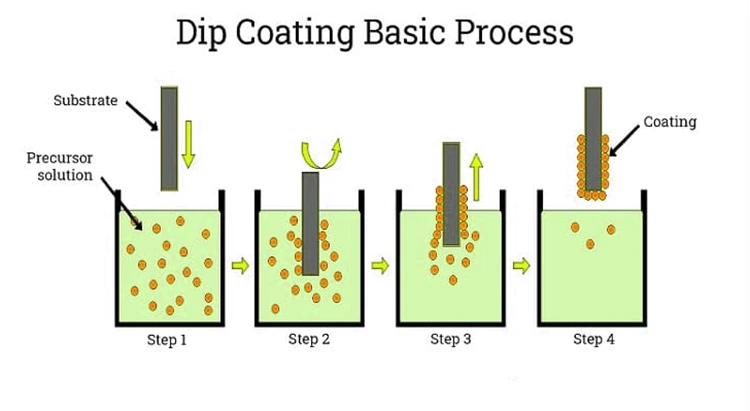

Dip Coating

Dipping coating process

Dip coating is a simple and low-cost method for coating objects of almost any shape and size (including very large objects and objects with complex surfaces). This is done by immersing a part in a liquid coating such as resin, polymer or epoxy and slowly pulling it out. The coating thickness varies according to the duration of dipping, withdrawal speed, coating thickness and temperature and post-curing step.

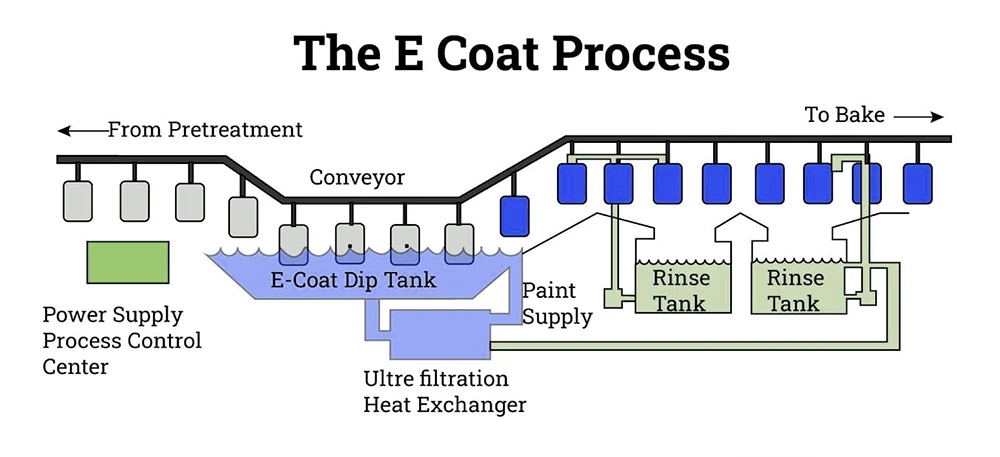

E-Coat (Electrophoretic Painting)

E-Coat process Electrophoretic Painting

An E-coat is a paint application using electrical current that lays down a smooth and even layer of paint. The component is then immersed in a bath of water-based paint that is charged electrically, causing the charged paint particles to attach themselves firmly to the surface, including hard-to-reach corners and holes. Suppliers use multiple dipping techniques for this method to be invented, which provides perfect coverage, robust protection from rust, great resistance to corrosion, chemicals, and salt spray.

Brushing

Brushing coating

Brushing, as a hands-on approach, involves applying coatings with a brush perfect for small-scale applications, touch-ups, repairs or hard-to-reach locations, such as inside corners, welds or pipe fittings. Not sounding all that speedy, nor exceedingly sporty, however practical in its painstaking detail, or downsized tasking, if ever a high floor-price paint-coding feels in order. The kind of brush is important and has to be compatible with the material being coated. With brushing it might take several layers to achieve the required thickness, but it is cheap, quick to deploy and useful for on-site repairs or late design changes.

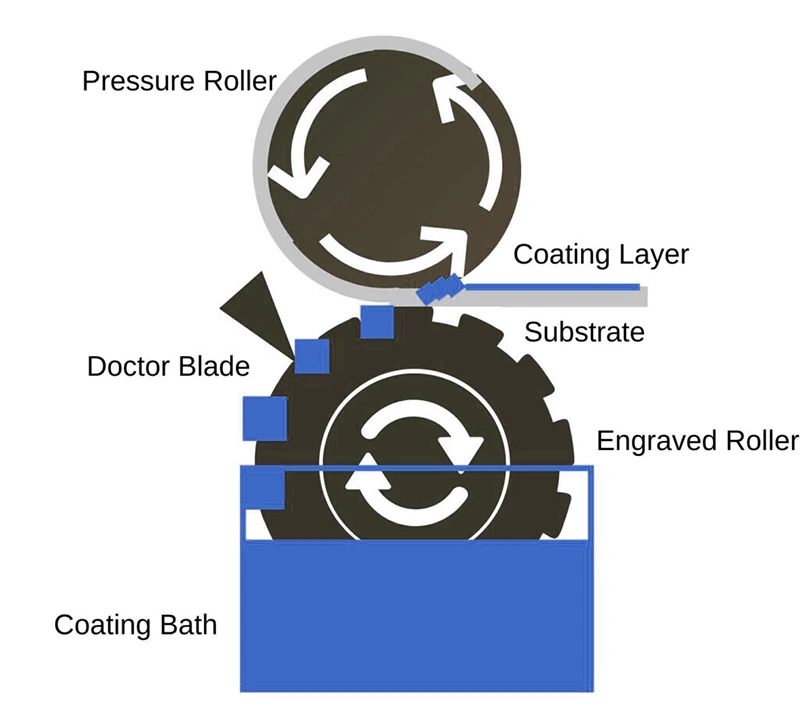

Roll Coating

Roller coating process

The Roll coating method is ideal when coatings need to be applied in uniform layers across large, flat surfaces such as metal sheets, plastics, or panels. Manual or fully automatic, making it suitable for large-scale production lines like coil or panel coating. Rollers spread the coating uniformly and have very fine control over thickness. Quick, efficient and involves no waste.

Spraying

Carry out the Paint Spraying Process

The application of coating with a spray gun or an automated system over a large or irregularly shaped part is referred to as spray coating. It’s multipurpose, fast, and effective on cars, steel beams, and electronics. Spraying offers the ability to get into hard-to-reach areas, and can be used for both thin paints and thick protective coatings. Some of these include adjusting the air quality and calibrating the equipment. Overspray and surface blemishes may occur, but experienced operators and solid process control yield a good surface finish.

Thermal Spray Coating

Thermal spraying is where you melt materials (metals, alloys, or ceramics) and then spray them onto a surface, forming a tough, protective layer. Common applications are for rebuilding worn components or improving their resistance to heat, corrosion or wear. Thermal spraying is common in heavy-duty application industries such as aerospace, power generation, and oil & gas and allows fabricating with a broad spectrum of materials with excellent bond strengths and coating strengths. Depending on the application and type of material, different techniques (plasma, flame, arc) may be more appropriate.

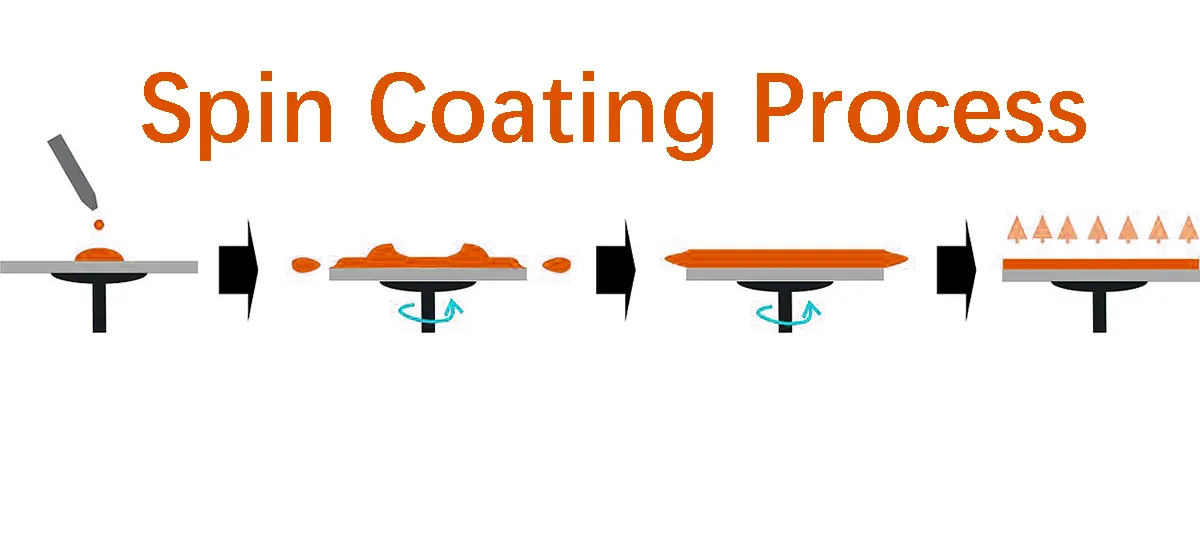

Spin Coating

Spin coating process

Spin coating is an electronics and laboratory process that uses a high-speed rotating disc to produce thin, uniform coatings on flat surfaces, such as glass wafers or chips. A thin film of liquid is placed in the center, then the object is spun at a high speed and the layer is evenly distributed by centrifugal force. It’s well-suited for ultra-wee films applicable in semiconductors or optics.

Flow Coating

Flow coating works well on flat or large horizontal parts that cannot be dipped, such as panels or glass. The liquid coating is applied to the surface in a controlled stream and does not require immersion. It’s low waste, speedy, and it can create thicker layers in one pass.

Slot Die Coating

Slot die coating is a very accurate method of coating thin and uniform layers of material onto a substrate, making it an important step in the production of many advanced products such as solar cells, batteries or flexible electronics. A slit is then used to apply the coating directly at the surface while the material to be coated slides underneath it.

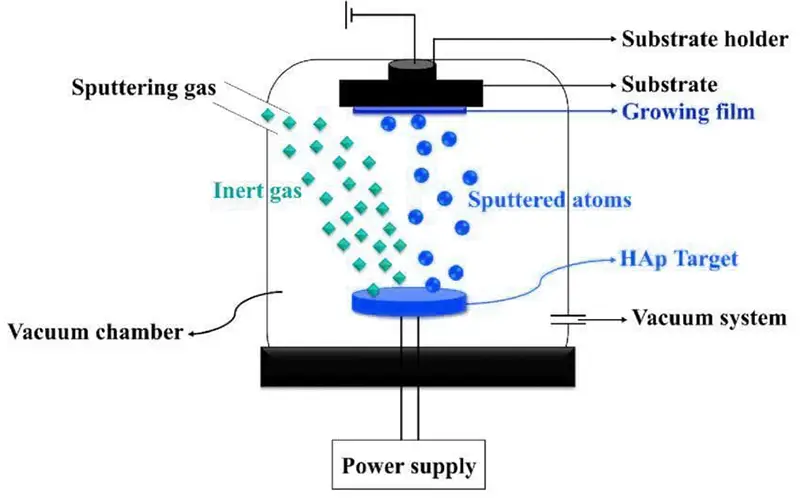

Physical Vapour Deposition (PVD) Coating

Principle of Physical Vapor Deposition

PVD is a vacuum-based, high-tech process that applies atom-by-atom ultra-thin, durable coatings to surfaces. This is utilised in both decorative and functional coatings, enhancing hardness, wear-free nature, corrosion and/or smoothness. It is clean, environmentally friendly, and great for applications requiring high strength and a fine finish, with a variety of materials and colours used.

Industrial Coating Application Techniques – Comparison Table.

| Method | Principle | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|---|

| Dip Coating | Substrate immersed in liquid coating, then withdrawn and cured | Uniform coverage (internal & external), suitable for complex shapes, scalable | Coating runoff, excess use, drying/curing time | Automotive parts, electronics, aerospace components, corrosion-resistant tools |

| E-Coat | Electric current deposits charged paint from a water-based bath | Even film build, excellent for complex shapes, corrosion resistance, and environmentally efficient | Requires conductive substrates, expensive setup | Automotive chassis, appliances, HVAC, structural parts, pipelines |

| Brushing | Manual application using brushes | Low cost, targeted application, minimal waste, good for touch-ups | Labour-intensive, inconsistent thickness, slower for large areas | Maintenance, weld seams, bolts, irregular joints, and field repairs |

| Roll Coating | Coating transferred via rollers onto flat surfaces | High throughput, consistent film, energy-efficient, automated | Limited to flat surfaces, not for recessed parts | Sheet metal, architectural panels, appliances, and continuous manufacturing |

| Spraying (Air/Airless) | Coating atomised and sprayed via air or high pressure | Covers large, complex shapes; fast; versatile for various viscosities | Overspray, VOC emissions, and equipment maintenance | Structural steel, vehicles, machinery, architectural surfaces |

| Thermal Spray | Heated material (wire/powder) projected onto the surface at high velocity | High durability, wear/corrosion resistance, substrate flexibility | Expensive equipment, skilled operation required | Turbines, aerospace parts, mining tools, remanufactured machine components |

| Spin Coating | Coating spread by centrifugal force on spinning flat substrates | Ultrathin, uniform layers; precise; repeatable | For flat, small parts only; edge bead formation; sensitive to defects | Semiconductors, optics, MEMS devices, R&D applications |

| Flow Coating | Liquid coating flows over a stationary substrate | High efficiency for large panels, good coverage, and low waste | Limited to simple, horizontal shapes; may not suit 3D geometries | Glass panes, auto panels, sheet goods, architectural elements |

| Slot Die Coating | Pre-metered coating delivered through a narrow slot onto a moving substrate | Uniform, high-speed, scalable, supports multilayers | Complex setup; requires precise material control | Batteries, solar cells, flexible electronics, barrier films |

| PVD Coating | Vaporised material deposited in a vacuum chamber as a thin film | Ultra-durable, decorative, functional (wear, corrosion, conductivity); eco-friendly | High capital cost, vacuum environment required, limited thickness | Cutting tools, microelectronics, optical lenses, aerospace parts, cookware, medical implants |

Quality Control and Inspection of Industrial Coatings.

Quality control in industrial coatings is critical to ensure the longevity, functionality, and protective performance of a coating system. The process encompasses a series of rigorous inspections and tests that occur before, during, and after coating application. These steps are essential to verify that the coating adheres properly, meets design specifications, and performs under intended environmental conditions. Below is a comprehensive breakdown of key quality control points during and after the coating process.

Quality Control and Inspection of Industrial Coatings

Surface Preparation

The preparation of the substrate must be very thorough before any coating is added. This step is frequently seen as the most significant, as a coating will never perform as expected if it is not adhered to a properly prepared substrate.

The first is cleanliness. Clear away any oils, greases, salts and other impurities. Soluble salt testing (Bresle test, for example) is also used to determine the level of salts which may cause osmotic blistering if not removed. Visual cleanliness is examined according to ISO 8501, and standard reference pictures for acceptable surface states are referenced.

Another important area is the surface topography, more commonly known as the anchor profile. This roughness provides mechanical adhesion of the coating to the substrate. Surface paint profile testing includes readings obtained by replica tape, digital profilometers, or visual comparators. According to ASTM D4417, the profile depth must be within the range specified by the coating manufacturer, typically between 40 to 100 microns for many protective coatings.

It is also required that the environmental conditions are highly shiny on the stage. Surface temperature, air temperature, relative humidity, and dew point are monitored with calibrated devices. Coating of the surface should only be done when the surface temperature is 3°C above the dew point to avoid condensation of water, which affects adhesion of the paint.

Measuring wet film thickness (WFT) while applying paint can assist in achieving the specified dry film thickness. If the coating is too thin, it may not offer the necessary protective qualities, while if it is too thick, it may also be runny, sag, or not cure correctly. WFT is determined with a notched gauge or a comb directly after application. Such readings assist the applicator in modifying the spraying practice or coating weight at the time of treatment. The expected DFT is obtained by multiplying the WFT by the % by volume of solids of the coating. Thus, if the coating is 65% solids and WFT is 150 microns, then cured thickness will be around 98 microns.

When the coating is hard and dry, the thickness of the dried film is also tested, since this figure is directly related to the capacity of the coating to protect. Non-destructive meters are commonly used to accomplish this. Magnetic gauges are for ferrous surfaces, and eddy current gauges are for non-ferrous materials, such as aluminium. Ultrasonic gauges, or even XRF tools, can be used on multilayer or very thick systems to measure the total build-up without “killing” the coating.

In some cases, destructive testing using a Tooke gauge may be required. This device cuts a groove through the coating to expose the layers, allowing the inspector to measure their thickness with high accuracy, especially when validating system build-up during failure investigations or quality audits.

Adhesion is one of the most crucial characteristics of a coating, in particular in severe conditions. It is tested by several methods for the adhesion of the coating to the substrate. The cross-cut or cross-hatch test, as laid out in ASTM D3359, includes scoring the coating in a grid, applying adhesive tape on top of it and then pulling the tape off to see how much of the coating comes off. The adhesion quality is rated a scale of 0B (complete removal) to 5B (no removal).

An alternate common test is the pull-off test (ASTM D4541) in which hydraulics is used to measure the force necessary to pull off a metal dolly bonded to the coating. This test, which yields a numerical value of the adhesion, in psi or MPa, is particularly useful for coatings that will be in structural service or sustained tensile and compressive stress. The less common scrape adhesion test entails the application of increasing levels of mechanical force until the coating shows proper failure. This is handy for comparative panel tests or QA labs.

Visual inspection is crucial during application and curing to detect defects such as pinholes, craters, sags, runs, blisters, or contamination by foreign substances. Such imperfections can compromise the strength of the coating or act as pathways for moisture to stimulate corrosion.

Holiday testing is done to identify any hidden flaws. The detection in thin films is done using a low-voltage wet sponge tester, which activates an electrical circuit when a break in coating occurs In the case of thicker coatings, a high-voltage spark test is performed, where a probe outlines the surface and a voltage is applied to find voids or holidays without damaging the coating.

Following curing, the mechanical integrity of the coating must be examined. The pencil hardness test (ASTM D3363) measures scratch resistance with an increasing hardness of pencils. Depending on the application, other tests may also be performed, such as pendulum hardness (König or Buchholz methods) and impact resistance. Another important trait is flexibility, as in the case of substrates that easily expand or contract. Mandrel bend or conical bend tests evaluate the ductility of the coating by measuring the ability of a coating to deform without cracking. These results guarantee that the coating can endure both mechanical stress and physical stress without losing its adhesive or integral property.

Industrial coatings must also meet visual and performance expectations. Colourimeters and gloss meters are used for colour and gloss measurements in order to maintain consistency over large areas, particularly for architectural or commercial uses. Simulated environmental conditions to enable performance testing of protective coatings are important. These tests measure coating durability based on exposure to salt spray (ASTM B117) or other cyclic corrosion testing. Those accelerated ageing tests can indicate how a coating system might perform in the field over time.

A key part of the inspection process is thorough documentation. Inspectors shall keep accurate logs of all environmental conditions, surface preparation, film thickness readings, adhesion tests, defects and defect repairs, and equipment calibration records. This will be specified in the project, and it acts as a legal record for future warranty claims or maintenance.

Inspection reports are required to correspond with the project-specific inspection and test plans (ITPs) for the scope of work, testing frequency, method, and acceptance criteria. These plans are made according to ASTM, ISO 12944 or NACE/AMPP specifications.

Quality control must align with internationally accepted standards. Key references include ASTM D1186, D3359, D4417, D4541, and D3363, as well as ISO 12944 for corrosion protection systems. Organisations like NACE (now AMPP), SSPC, and FROSIO provide training and certification for coating inspectors. A certified inspector ensures that inspection protocols are properly applied and interpreted, increasing confidence in the quality and performance of the finished system.

Industrial coating inspection is a multileveled process with elaborate activities like surface analysis, environmental monitoring, physical testing, and documentation. Proper quality control ensures that these coatings not only have the desired aesthetic and mechanical properties but will perform reliably in the environments for which they are intended. The compliance with standardised procedures and conducting inspections by qualified personnel helps provide protective coatings with the highest possible durability, safety, and lifecycle value.

Handling and Applying Industrial Coatings Safely.

One of the employees working on a medium-sized manufacturing plant last year collapsed on a routine paint job; he was hospitalised. The cause? A solvent-based coating fumes in a poorly ventilated place, and I did not see a single respirator. It became a wake-up call to the company, which had gotten comfortable with its minimal safety precautions. Paints, epoxies, and powder coatings fall under the umbrella of industrial coatings and are used in construction to protect surfaces, vehicles, and equipment from corrosion, wear, and weather. But these products are full of dangerous chemicals that are quite literally deadly when not properly used. Implementing the specific equipment, engineering controls, and training for worker safety during coating operations will help keep workers safe while complying with safety regulations.

Handling and Applying Industrial Coatings Safely

Personal Protective Equipment (PPE)

Firstly, one of the first levels of protection for those applying industrial coatings on the construction site is their personal protective equipment (PPE). Depending on the task and the chemicals involved, particular forms of PPE protect specific portions of the body.

- Eye and Face Protection: Face shielding devices, such as full face shields, offer extra protection when operations include spraying under high pressure or transferring solvents that may create splashes and airborne particulates.

- Respiratory Protection: Paints and coatings containing solvent vapours and isocyanates can also pose a significant risk by damaging the airways. A half mask or N95 mask with organic vapour cartridges will work well in case of adequate ventilation; otherwise, use a NIOSH-approved mask as per NIOSH guidelines in a well-ventilated area. On the other hand, if working in a confined space or with a very volatile coating, PAPR or a supplied-air respirator (either SAR/SCBA) may have to be used.

- Skin Protection: Workers should wear nitrile or neoprene gloves resistant to solvents. Standard work gloves are inadequate. Full-body chemical-resistant coveralls and rubber boots protect against skin exposure during mixing, spraying, or cleaning.

- Training and Hygiene: Merely wearing PPE isn’t enough. Workers must be trained on its correct use: how to put it on (donning), take it off (doffing), and dispose of or clean it properly. Eating, drinking, or smoking in application zones should be strictly prohibited to prevent ingestion of chemicals.

Ventilation Requirements

Ventilation is a crucial control measure to prevent inhalation of hazardous fumes or airborne dust. Proper ventilation not only protects workers but also helps keep vapour concentrations below dangerous levels.

- Local exhaust ventilation should be installed at the source of emissions, such as spray booths or mixing stations, to capture fumes at the point of generation.

- General exhaust systems can circulate and dilute vapours in open or semi-enclosed areas.

- Ventilation must direct air flow away from workers and ignition sources, and outside the building when possible.

Solvent vapours are explosive between their Lower and Upper Explosive Limits (LEL/UEL). Work must be stopped if vapours approach 10% of the LEL. Use calibrated gas detectors in enclosed environments to monitor conditions in real-time. Powder coatings pose a unique risk: combustible dust. Ventilation systems must be explosion-proof and dust-tight. Dust accumulation on surfaces, beams, or duct interiors can lead to catastrophic explosions if ignited. Even after application, ventilation must continue. It takes time for vapours to dissipate. Re-entry should only occur after air testing confirms safe levels.

Fire and Explosion Prevention.

Flammable solvents are a major hazard when applying industrial coatings. Most coatings have solvents with flashpoints under 200°F, and vapours can ignite in low areas if these solvents are utilised within a restricted area, due to static electricity, hot surfaces, or open flames. Flammability data from the product SDS must be understood by workers, and all ignition sources must be kept at bay. Flammable materials should not be permitted if there is smoking, hot work or use of non-rated electrical devices. In classified areas, tools and lighting should be explosion-proof rated.

Explosions can be triggered by static discharge in liquid transfer or spray. Containers, hoses, and sprayers must be electrically grounded and worn in a way to allow dissipation of static charges. Dust hazards are regulated by OSHA under the National Emphasis Program. A good strategy to prevent combustible dust includes regular cleaning to eliminate settled dust, proper handling of the material, and spark-proof tools.

Interpreting Safety Data Sheets (SDS)

Every industrial coating product comes with a Safety Data Sheet. It is vital to read and understand these documents before starting work.

Key SDS Sections to Know:

- Lists hazards, pictograms, signal words (e.g., “Danger”), and safety instructions.

- Contains fire-fighting measures and the type of extinguishers to use (e.g., CO₂, dry chemical, foam).

- Covers safe storage, ventilation, and handling procedures.

- Specifies PPE and occupational exposure limits.

- Technical data including flash point, autoignition temperature, and explosive limits.

Always check the SDS for flash point, vapour hazards, required PPE, grounding needs, and appropriate fire response. Keep SDSs accessible at the jobsite and train workers on how to read them.

Practical Safety Best Practices

- A strong safety culture goes beyond equipment and documents; it’s built into daily work habits.

- Before starting, assess hazards such as confined spaces, high flammability coatings, or inadequate ventilation. Adjust controls accordingly.

- Inspect all spray equipment, compressors, hoses, and ventilation systems regularly. Failures can result in spills, leaks, or dangerous pressure buildup.

- Clean spills immediately using inert absorbents like sand or clay. Never use sawdust—it can ignite if it absorbs solvent vapours. Keep storage areas orderly and ventilated.

- Keep fire extinguishers (CO₂, dry chemical) close to work zones. Ensure that at least one person on each shift is trained in evacuation, spill containment, and first aid.

- Promote continuous safety training. Encourage workers to report near misses and unsafe conditions without fear of reprisal. Make PPE and SDS reviews part of routine toolbox talks.

- Apply the Hierarchy of Controls: Remove hazards first, then apply engineering solutions before relying on PPE.

- Use ventilation as your primary safeguard—never assume PPE alone will protect you from vapours or dust.

- Treat every job as unique: review the SDS, assess risks, and plan emergency response.

- Stay vigilant. Fire and explosion risks are real, especially with volatile solvents and powders.

By following these comprehensive safety practices, construction teams can effectively minimise the risks associated with industrial coatings, ensuring a safer work environment and compliance with regulatory standards.

How to Maintain and Extend the Service Life of Industrial Coatings?

Industrial coatings come in to play an important role in protecting the construction materials from corrosion, abrasion, UV damage or chemical exposure. But they are only effective if maintained and repaired timely manner. In other words, a properly maintained coating will outlast, outperform and result in you saving money over the long term, as your repair and replacement costs would be lower.

Extend the Service Life of Industrial Coatings

Conducting Regular Inspections

Scheduled inspections should be conducted every three to six months, depending on the type of coating and the environmental conditions. More frequent inspections may be needed for locations exposed to salt, moisture, or chemical fumes, such as coastal or industrial areas.

These assessments, are oriented towards detecting early warning signs of decline. Such as cracking, bubbling, peeling or patchy spots of colour. If you notice surface rust or streaking, that protective coating may have been breached, allowing moisture to come in contact with the substrate. Documenting these findings with notes and photographs, wear patterns, or repeat damage can be monitored over time, helping to prioritise repairs and plan preventive action.

Cleaning and Surface Care

Left uncleaned and unattended, dirt and grime backed by pollutants spoil the aesthetic charm of coatings and contribute toward premature wear by trapping moisture and chemicals onto the exposed surface. Cleaning it regularly would maintain the coating quality.

For most environments, cleaning should occur at least twice a year. Surface dust can usually be removed with a low-pressure rinse with clean water. In places of heavy buildup around exhaust vents or along roads, a mild detergent may be necessary. You must stay clear of stiff brushes or aggressive solvents because they, too, will scratch or dull that protective finish. Always rinse well to remove any cleaning residues.

For areas where biological growth may occur, especially shaded or moist areas, further treatment with a permitted biocide may be required. The stain not only forms on the coating but also mould or algae can also degrade the chemical structure of the coating as time goes by.

Localised Repairs and Touch-Ups

Damage of any size to coatings must be repaired as soon as possible. If neglected, even small scratches or hairline cracks can permit moisture and oxygen ingress beneath the coating, resulting in rust, delamination, or other coating failures.

If something is damaged, strip the area and clean and that might mean sanding the area, sanding with a wire brush or solvent cleaning to get grease or contaminants off the surface, etc. If there is bare metal, a compatible primer must be applied before the repair coating. You will want to stay within the original product as far as composition so that the touch-up is chemically compatible and adheres properly. Cure the repaired area prior to taking it back into service after application.

Consistency is key. Repairs should be aligned with the technical specifications provided by the manufacturer, including ambient conditions such as the humidity and temperature at the time of application.

Conducting Regular Inspections

Scheduled inspections should be conducted every three to six months, depending on the type of coating and the environmental conditions. More frequent inspections may be needed for locations exposed to salt, moisture, or chemical fumes, such as coastal or industrial areas.

These assessments, are oriented towards detecting early warning signs of decline. Such as cracking, bubbling, peeling or patchy spots of colour. If you notice surface rust or streaking, that protective coating may have been breached, allowing moisture to come in contact with the substrate. Documenting these findings with notes and photographs, wear patterns, or repeat damage can be monitored over time, helping to prioritise repairs and plan preventive action.

Preventive Practices and Environmental Controls

Preventive maintenance extends beyond the coatings themselves. It includes controlling the factors that contribute to coating degradation. As an example, check that drainage channels and rain gutters are working to minimise water pooling or surface runoff. In areas that are heavily used, protective guards or barriers can help to prevent mechanical damage due to equipment or foot traffic.

Planning for Recoating

However, all coatings, even the best-maintained, will reach their end of service life eventually. Planning for recoating prior to total loss of protective properties, as opposed to waiting until catastrophic failure, is a rational decision.

You start with a visual inspection of the current coating and conduct adhesion testing to assess its condition. Surface preparation may only include cleaning and roughening of sound existing layers. More extensive removal might be necessary if the failures are widespread. To ensure the compatibility of a recoating system, it should always be used under the original manufacturer’s specifications.

To keep that system running smoothly, it’s essential to work with industrial coating suppliers who understand not just how coatings are applied, but how they behave over time. This directory web is here to help you identify those partners, experienced manufacturers and service providers who can support every stage of your coating’s lifecycle, from selection and application to inspection and long-term care. Taking that step today means fewer breakdowns, fewer surprises, and greater confidence in your investment for years to come.

To keep that system running smoothly, it’s essential to work with suppliers who understand not just how coatings are applied, but how they behave over time. Our website directory is here to help you identify experienced manufacturers and service providers who can support every stage of your coating’s lifecycle, from selection and application to inspection and long-term care. Taking that step today means fewer breakdowns, fewer surprises, and greater confidence in your investment for years to come.

FAQs

What are the applications of industrial coating?

Such coatings are often used to protect materials such as concrete and steel. In addition to that, industrial coatings also aid in improving the fire and other safety resistance of certain materials.

What is the application of coating material?

A coating material is used to cover the surface of an object and to enhance its life of the object. The purpose of applying the coating on the object’s surface is to decorate it and protect it from external factors, i.e. light, rain, cold, humidity, air, heat, etc.

What are the applications of surface coatings?

Surface coatings are also crucial for aircraft and defence equipment, protection against environmental elements, and improving performance. Additionally, coatings are applied to buildings and infrastructure to enhance weather resistance and longevity.

What are the factors affecting the coating process?

Several dynamics, including the following, decide coating quality:

- The film’s (coating’s) reflectivity.

- The uniformity of film thickness.

- The stress of the film.