Have you ever spent hours honing a paint job just to have little bubbles or streaks appear when it dries? Isn’t it awful to have to start again on all? Often, that annoying result may be traced back to one vital action: how you combined your paint.

For a smooth, long-lasting finish, getting mixed paint right—whether it’s a bespoke hue, difficult epoxy, or just achieving that ideal consistency—is very vital. But getting it incorrect? That’s when those annoying problems begin.

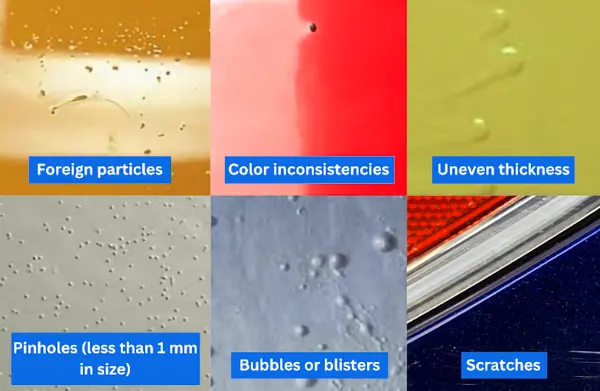

Rest assured, we have you covered. From the appropriate instruments to safety advice, this tutorial covers the fundamentals of correctly Mixing Paint. We’ll address typical Paint Defects that appear during application—think unevenness or pinholes—and demonstrate how to prevent or correct them. In addition, useful advice on Storing Mixed Paint so your leftovers are prepared for following time. Let’s make your paint projects perfect!

How to Properly Mix Paints?

Okay, you’ve chosen your color, purchased all the components you need, and are ready to mix them together. But wait… did you actually know how to mix them?

It’s easy to overlook, but getting your paint properly mixed is where a nice finish truly begins, long before you dip a brush or load a sprayer. Imagine it is like cooking: you wouldn’t forget to correctly prepare your ingredients and hope for a great dinner!

The right Mixing Paint steps make sure that the custom color mixing is perfect from top to bottom, that the consistency runs perfectly for easy application, and that the paint does what it’s supposed to do, which is protect and beautify. But it’s not just about avoiding annoying problems later on; it’s also about getting that perfect, professional look you want and making sure that all of your hard work lasts.

Essential Equipment for Mixing Paints.

You don’t need a full-blown workshop to mix paint like a pro—but the right tools? They make all the difference. A few well-chosen essentials can turn guesswork into a smooth, consistent blend every time.

Essential Equipment for Mixing Paints-Mechanical Mixers

- Containers: Graduated cups or buckets with clear markings are vital. They help you accurately measure paint, hardeners, and thinners. Straight-sided containers are generally better than tapered ones for precise volume measurements, especially for Twocomponent paint systems. Disposable or silicone cups are great for easier cleanup, particularly with sticky materials like epoxy.

- Measuring Tools: Besides the graduated cups, digital scales offer great accuracy, especially when manufacturers specify weight-based ratios. This is common for industrial or automotive paints.

- Stirring Tools: Simple, sturdy paint stir sticks work for smaller jobs. Avoid flimsy ones that might break or shed material.

- Mechanical Mixers: It is much better to use an electric or gas drill with a mixing blade tool for bigger batches of paint or paint that is thicker. These mix everything well without adding too many air bubbles. For art paints that come in small bottles, a paint shaker or a vortex mixer works great.

- Paint Strainers/Filters: It eliminates any clumps, dried bits, or other waste, this helps to keep the spray gun from getting clogged and have a better finish.

- Funnels: Allows you to pour the product smoothly into spray gun cups or smaller containers, so reducing spillage.

Crucial Safety Gear You Shouldn't Skip.

Mixing paint isn’t just about color—it’s a chemical cocktail. From bold pigments to harsh solvents and VOCs, what gives your finish its beauty can mess with your health if you’re not careful. Gear up with proper PPE—it’s not optional, it’s your first line of defense.

- Gloves: You must wear nitrile gloves or gloves that are immune to chemicals. They keep your skin from getting irritated and chemicals from getting into it.

- Safety goggles: Keep splashes and fumes from getting into your eyes. It only takes one drop to do a lot of damage.

- Mask for your nose and mouth: This is very important when dealing with solvent-based paints or in places where air flow is low. To get rid of dangerous fumes, wear a mask with the right cartridge (usually organic vapor).

- Coveralls, an apron, or old clothes will keep paint off of your face and nice clothes.

- Good Air Flow: You should always mix paint in a room with good air flow. If you can, open the windows and doors, use an air fan, or work outside (but watch out for dust). For paints that can catch fire, make sure the wiring is right to avoid static electricity.

Step-by-Step Paint Mixing Process.

Before you start mixing take a beat—these steps aren’t just routine, they’re your roadmap to a smooth, safe mix every time. Skipping them? That’s how mistakes sneak in.

- Read the Material Safety Data Sheet (MSDS/SDS): Every paint product comes with an MSDS (or the newer SDS format). Read it. It contains vital info on Paint Mixing Ratios, safety precautions, hazards, and what to do in an emergency. It might specify ideal mixing temperatures or warnings about mixing certain components.

- Check Batch Numbers and Expiration Dates: If using multiple cans of the same color, or components like paint and hardener, check that the batch numbers match. This prevents slight color or performance differences. Also, check the expiration dates – old paint might not mix or cure properly. Store paints in cool, dry places away from sunlight.

- Use a Calibrated Mixer or Shaker First: If paint has been sitting, pigments can settle. Use a paint shaker (like those at the store) or a mechanical mixer to get the paint back to a uniform state before you start combining it with other components like hardeners or thinners.

- Accurately Measure for the Optimal Ratio: This is critical. Follow the manufacturer’s recommended Paint Mixing Ratio exactly (e.g., 4:1, 2:1:1). Use your graduated cups for volume or a scale for weight, based on the instructions. Don’t guess or estimate. Being off even a little can affect drying time, durability, and finish quality. For example, a 4:1:10% ratio means 4 parts paint, 1 part hardener, and then 10% of that combined total volume added as thinner.

- Follow the Recommended Mixing Time: Stir thoroughly but gently. You want everything blended, but vigorous stirring can introduce air bubbles, leading to Paint Defects. Manufacturers often suggest a mixing time (like 1-2 minutes). For two-part paints (like epoxies), there might be an “induction time” or “sweat-in time” – a waiting period after mixing (maybe 10-30 minutes) before you use the paint. This allows the chemical reaction to start properly. Keep an eye on the pot life (how long the Mixed Paint stays usable).

- Filter Before Application: Always strain your Mixed Paint through a filter just before you put it in your sprayer or tray. This catches any last bits of debris or clumps, ensuring a smooth flow and preventing surface imperfections. Use a funnel for clean pouring.

Helpful Mixing Tips for Success.

Beyond the basic steps, a few extra pointers can make your Mixing Paint process smoother:

- Pay Attention to Environmental Factors: Aim for the manufacturer’s recommended temp, usually around 65–75°F (18–24°C). Cold slows things down; heat speeds things up (sometimes too much, shortening pot life). High humidity is bad, especially for certain paints, as it can trap moisture and cause paint defects like blushing. Try to work in drier conditions if possible. Good airflow is crucial for safety (fumes) and helps with proper drying. Avoid dusty or windy spots that can introduce contamination.

- Choose the Right Tools: Mechanical mixers are worth it for larger jobs or thick materials. Paddle choice matters too – some are better for thick stuff, others for liquids. For small hobby bottles, a vortex shaker is fast and effective. Precision scales remove guesswork for weight-based ratios.

- Allow Enough Time: Don’t rush the Mixing Paint stage. Ensure everything is fully blended. If there’s an induction time, respect it. It’s better to take an extra minute here than deal with Paint Defects later. Maybe test a small amount first if unsure.

- Clean Tools Immediately: Dried paint is hard to remove and can contaminate future mixes. Clean everything right after use.

- Avoid Overmixing: Especially with epoxies or gloss paints, mixing too fast or too long can whip air into the paint, causing bubbles in the final finish. Gentle and thorough is the goal.

- Use Quality Materials: Good quality paints, hardeners, and thinners generally mix better and give more predictable results.

- Keep Records: Note down the ratios, batch numbers, and conditions for successful mixes. This helps replicate results and can be useful for tracking.

Think of mixing paint like tuning an instrument—get it right, and everything that follows sings. Take a few extra minutes now, and you’ll see it in every smooth stroke and long-lasting finish later. Some partners may feel that it is too troublesome to do it themselves, and finally decide to buy ready-made products directly. However, there are also many things to pay attention to when purchasing mixed paints, which can be found in another blog.

Common Problems with Mixed Paint Applications.

So, you’ve meticulously measured, stirred, and gotten your Mixed Paint looking perfect in the can. You’re feeling confident. You start applying it, and everything seems smooth… until it dries, and suddenly, there they are. Tiny little craters, streaks, or maybe the paint is just sliding down the wall. Argh! It’s incredibly frustrating when, despite your best efforts at mixing, Paint Defects show up during or after Paint Application. But don’t worry, you’re not alone! Understanding these common issues – like uneven coating, pesky pinholes, annoying sagging, or cloudy blushing – is the first step to troubleshooting and getting the flawless finish you’re really aiming for when working with Mixed Paint.

Common questions about mixed paint

Here is a table with some typical defects, what they might look like, why they occur, and how to correct them.

| Defect | Description | Root Causes | Solutions |

|---|---|---|---|

| Uneven Coating | Patchy, streaky, or orange peel texture | Improper mixing, incorrect application, cold/hot temperatures, contaminated/poorly prepared surfaces | Mix thoroughly with agitators, adjust spray settings and train applicators, maintain 60–85°F and <70% humidity, clean and prime surfaces |

| Pinholes | Tiny holes or craters in film | Trapped air/solvents from mixing or spraying, moisture on substrate, thick coats and wrong thinner, porous substrates | Mix slowly using defoamers, control humidity and preheat substrates, apply thin coats with correct thinners, seal porous surfaces |

| Sagging | Drips, runs, or curtains on vertical surfaces | Excessive paint application, over-thinning or slow thinners, high humidity or low temperatures, vertical surfaces | Apply thin coats with steady spraying, use correct thinner/ratio, maintain 60–85°F and moderate humidity, increase viscosity |

| Blushing | Milky, cloudy haze on surface | High humidity or cold surfaces, fast-evaporating thinners, poor ventilation, heavy spraying | Paint at <70% humidity and >60°F, use slow retarders, ensure ventilation, apply thin coats and adjust pressure |

Paint defects don’t just appear out of nowhere—they’re often warning signs that something went off in your prep, mix, or application. Spotting them early (and knowing why they happen) gives you the upper hand. Prep well, follow the manufacturer’s playbook, and if issues pop up, you’ll know exactly how to fix them—fast. In order to avoid these problems, I recommend that every member involved in mixing paint should have a clear understanding of the types of mixed paint base systems.

How to Store Mixed Paint Properly?

You know that feeling? You just finished a paint project, feeling proud, and you stash the leftover paint away “just in case.” Then months later, you need a quick touch-up for a small scuff… you open the can, hoping to find that perfect custom color, only to discover a dried-out, unusable brick. What a waste!

Don’t let your perfectly Mixed Paint meet that sad fate! Whether you have leftover custom colors or just didn’t use the whole batch, proper Paint Storage is absolutely key to keeping it usable for those crucial touch-ups or future projects. Its main enemies are lurking everywhere: air, temperature swings, and contamination. Here’s how to store paint effectively and save yourself future frustration:

1. Use Airtight Containers

Air contact is the main reason paint dries out, gets a skin, or breaks down. If the paint is clean and not damaged, keep it in its original can for the best seal. Wipe the rim clean before closing the can. For smaller amounts, use solid HDPE plastic containers with strong lids or sealed mason jars. Stay away from plastics that are easily broken or that leak air. For metal cans, gently tap the lid shut with a rubber mallet to prevent denting; to limit air, move leftovers to smaller containers, apply plastic wrap straight on the paint surface before sealing. Storing cans upside down will help the paint seal against the lid and stop air entry.

2. Label Everything Clearly

Clear labels simplify paint search and track shelf life. For bespoke mixes, note the project or room (e.g., “Living Room Walls”), color name, manufacturer, mixing ratio, mixing date—critical for mixed paint, which may last up to 2 years or less with additions. For correct storage and use, specify the paint type—latex, oil, acrylic, epoxy. For fast identification, dab some paint on the lid using permanent markers on the container, masking tape, or adhesive labels.

3. Control Temperature and Humidity

Extreme temperatures and moisture are bad for stored paint.

- Ideal Temperature: Aim for a stable temperature between 50°F and 80°F (10°C–27°C). Avoid freezing temps (below 32°F/0°C), which ruin water-based paints like latex and acrylics. Extreme heat (above 95°F/35°C) can also degrade paint.

- Keep it Dry: Store paint in a low-humidity environment. Moisture can cause rust in metal cans or even mold growth in some paints.

- Best Locations: Think cool, dark, and dry places like interior closets, utility rooms, or climate-controlled basements.

- Avoid: Garages, sheds, attics, or near heaters/direct sunlight where temperatures swing wildly. If a garage is your only option, try to bring paints indoors during extreme weather. Don’t store containers directly on concrete floors, as moisture can wick up.

4. Avoid Contamination

Dirt, rust, or dried paint flakes can ruin your stored Mixed Paint.

- Clean Containers: Ensure any container you use is clean and dry. Don’t transfer paint into rusty cans – use plastic or glass instead.

- Prevent Debris: Wipe the container rim clean before sealing. If a skin has formed on the paint, carefully remove it before stirring. If bits break off, strain the paint before use.

- Use Clean Tools: Don’t introduce contaminants when transferring or stirring paint.

- No Cross-Mixing: Keep different types or brands of paint separate unless you know they are compatible.

By following these Paint Storage tips, you can significantly extend the life of your leftover Mixed Paint. Before using stored paint, always give it a good stir (check for separation or bad odors) and maybe test a small spot first. Proper storage saves money, reduces waste, and keeps your mixing paint colors ready for when you need them, helping you avoid future Paint Defects caused by degraded material. Taking care during Mixing Paint and Paint Application deserves follow-through with good Paint Storage practices.

How do you Mix Paint for a Spray Gun?

So you invested in a paint sprayer, dreaming of those ultra-smooth, professional results you see online. Faster application, perfect coverage… what’s not to love? But maybe your first attempt looked less like a factory finish and more like… well, slightly bumpy orange peel? Or maybe it just wouldn’t spray evenly? It’s a common headache! The culprit often isn’t the sprayer itself, but the paint. Straight-from-the-can paint is usually too thick for spraying. Getting that perfect, flowing consistency is the secret handshake to achieving those spray-gun dreams. Don’t learn the hard way; here’s how to mix paint properly for your sprayer.

Why Thin Paint for a Sprayer?

Ever wondered why your spray job looks more like orange skin than glass? That’s usually your paint crying out for help—specifically, a thinner. Spray guns work by turning paint into a fine mist, like fog rolling off a lake. But if the paint’s too thick, it can’t mist properly. Instead, you’ll get messy splatters, weird textures, or worse—a completely jammed nozzle. Thinning your paint helps it glide smoothly through the spray gun, giving you that silky, even finish you’re aiming for.

Steps to Prepare Paint for a Spray Gun.

- Know Your Paint: Different paints need different thinners. Always check the manufacturer’s label first!

- Latex (Water-Based): Thin with clean water. Often needs 5-10% water, maybe up to 20-25% for some guns/paints.

- Oil-Based (Alkyd): Thin with mineral spirits or paint thinner. Ratios vary, maybe 3:1 or 4:1 paint-to-thinner.

- Acrylic (Artist or Craft): If spraying (less common for fine art), thin with water or an acrylic airbrush medium. Ratios vary widely.

- Lacquer: Use lacquer thinner. Ratios are specific, often 2:1 to 4:1.

- Automotive Paints: Use specific reducers recommended by the manufacturer. Follow ratios exactly due to chemical reactions and toxicity.

- Safety First! Paint fumes, especially from thinners like mineral spirits and lacquer thinner, can be harmful. You should always: Work in a very well-ventilated area (outdoors is best, or a garage with doors open). Wear a respirator designed for paint fumes, not just a dust mask. Wear safety glasses and gloves.

- Stir and Strain: Paint settles over time. Stir the paint thoroughly in its original can first, scraping the bottom. Then, pour the paint through a paint strainer (a mesh filter) into a separate, clean mixing bucket. This removes any clumps, dried bits, or impurities that will clog your spray gun. Don’t skip this!

- Check Viscosity (Maybe No Thinning Needed?): Some newer paints or higher-powered sprayers might handle unthinned paint. Do a quick test: put a small amount of strained, unthinned paint in the gun and spray on cardboard. If it sprays evenly, great! If it sputters or looks chunky, proceed to thinning.

- Thin Gradually: Start with the manufacturer’s suggested ratio or a broad rule, say 10% water for latex paint. Add little amounts of thinner to the strained paint in a mixing bucket, swirling gently with a fresh stir stick or mixing paddle after each addition. Steer clear of all the thinner at once as over-thinning can cause drips, runs, and inadequate coverage. Though it’s tough to remove extra thinner, you may always apply additional thinner if necessary.

- Test the Consistency: Begin by testing the paint’s thickness with a couple of reliable methods to ensure it’s thinned right for spraying. Try the drip test by dipping a stir stick into the paint and lifting it out; the paint should trickle off slowly, similar to milk, for a few seconds. For a more precise check, use a viscosity cup like a Zahn or Ford cup—fill it up and measure the time it takes for the paint to flow out through the hole at the bottom, matching the ideal time listed in your spray gun manual or on the paint can. After that, run the paint into the spray gun, then try it onto a surface until you have a smooth, even mist free of spatter or heavy pouring, configure the spray gun including air pressure, fluid flow, and fan pattern.

- Adjust if Needed: If the paint doesn’t feel right, you need to make some changes. If it’s too thick and causes splattering or a bumpy, orange peel look, mix in a little thinner, about 5% at a time, stir well, and check it again. If it’s too watery and starts running or dripping, you’ve put in too much thinner; fix it by adding more unthinned, strained paint to make it thicker, or just start fresh with less thinner. Make sure to test it again after any tweaks to confirm the paint is good for spraying.

You’ve got this. Mixing paint no longer has to feel like guessing if you have the correct procedures under your belt. From dialing in the ideal mix to resolving those tough issues (spoiler: it’s generally the method or the environment), to smart leftovers storage—you’re now set up for success.

Learning these techniques can help you to save wasted paint, minimize annoying do-overs, and produce finishes that really highlight your effort. All set to go on? Visit coatingsdirectory.com, your go-to resource for the correct goods, professional contacts, and confident tackling of your next job.

FAQs

Why is checking the batch number important when Mixing Paint?

It ensures consistency; using Mixed Paint components from different batches can cause slight color or performance variations. Professionally, this step helps guarantee uniformity across a large project or when using multi-component systems.

What's the best temperature range to Store Paint?

Keep it stable between 50-80°F; this prevents freezing or overheating which can ruin Mixed Paint. Professionally, storing paint within the manufacturer’s recommended range (often 60-75°F) preserves its chemical stability and shelf life, avoiding Paint Defects later.

How can I fix sagging Paint Defects after application?

Let it dry, then sand smooth and repaint; applying thinner coats next time helps prevent Mixed Paint from running. Professionally, addressing the root cause involves adjusting viscosity, application technique (speed/distance), or environmental controls before recoating.

What does an MSDS tell me about Mixing Paint?

It gives crucial safety info and mixing instructions; always read it before starting any Mixed Paint job. Professionally, the MSDS (or SDS) details hazards, PPE requirements, spill procedures, and specific Paint Mixing Ratios or induction times vital for compliance and safety.

How long does properly stored Mixed Paint usually last?

Often up to 2 years if stored well; check for spoilage signs before reuse to avoid Paint Defects. Professionally, shelf life varies based on paint type and additives; always refer to manufacturer data and test stored Mixed Paint for usability.

Why do I need to strain paint before putting it in a spray gun?

Straining removes clumps or debris that will clog the spray gun’s nozzle. Paint, especially if stored, can contain small lumps, dried flakes, or impurities. Pouring it through a mesh paint strainer ensures only smooth liquid enters the sprayer, preventing clogs, spitting, and ensuring an even spray pattern.

How do I test if my paint is thin enough for a spray gun?

Use a viscosity cup or do a spray test on cardboard. A viscosity cup measures the time it takes for paint to drain, indicating thickness (check gun manual for ideal times). Alternatively, spray the thinned paint onto a test surface; it should form a fine, even mist without sputtering (too thick) or running excessively (too thin).