Article Chapters

In the coatings industry, the continuous emergence of new technologies drives the development and change of the industry. New technologies are reshaping the landscape, providing innovative solutions and pushing the boundaries of what is possible. From intelligent data-driven coating development to sustainable coatings to a variety of innovative coating technologies, these are bringing new possibilities to the coatings industry. Reimagining the future of how we protect and enhance surfaces. Join us as this article will explore new trends and technologies in the coatings industry, hoping to bring you inspiration and insights.

Intelligent data-driven development of new coatings

Background and Advocacy:

The coatings industry is increasingly embracing smart, data-driven approaches to new product development. One of the key drivers behind this trend is the increasing complexity of coating formulations and the need to optimize them for specific applications. Traditional trial-and-error approaches are time-consuming, expensive, and less feasible in today’s fast-paced business environment. With the advent of big data analytics and artificial intelligence, coatings manufacturers can now predict consumer trends, optimize recipes and streamline testing processes more accurately and quickly than ever before.

The Role of Data Analytics and Artificial Intelligence:

Data-driven technology plays a key role in determining the optimal composition of coatings to meet specific requirements such as durability, weather resistance or low environmental impact. By analyzing massive data sets on material properties, environmental conditions and consumer preferences, AI algorithms can come up with recipes that human researchers might not consider. This not only speeds up the research and development process but also opens up new possibilities for innovation.

For example: specially developed computer software can help paint companies optimize production plans and product mix to achieve the best results. AI also allows companies to quickly replicate experiments and prototypes while analyzing possible design flaws during the design phase. Intelligent systems can also use computer vision to spot errors and glitches, allowing engineers to quickly fix them. Intelligent data-driven development enables coatings development companies and application companies to analyze large amounts of data to identify patterns and trends, helping them drive coatings development efficiently and safely.

Future Growth Trends:

The integration of artificial intelligence and data analytics in coatings development is expected to accelerate, with more companies investing in these technologies to stay competitive. This trend could lead to smarter, more adaptable coatings that can change their properties in response to environmental changes. Another important aspect of this trend is the role of predictive analytics in predicting future trends and demand in the coatings market. By analyzing market data and customer preferences, companies can better predict market demand and develop coatings that better match customer expectations. In the future, we expect the application of intelligent data-driven development in the coatings industry to continue to grow. Not only does this approach help companies develop coatings more efficiently, it also allows them to innovate and stay ahead of the competition.

Applicability:

Intelligent data-driven development is particularly beneficial for industries where coating performance is critical to the longevity and functionality of the product, such as the automotive, aerospace and marine industries. It also holds great promise for the development of environmentally friendly coatings, as AI can help identify sustainable raw materials and processes that can reduce the carbon footprint of coatings.

Sustainable Coatings Technology Development

Background and Advocacy:

Sustainable coatings are an innovative technology that has attracted much attention in recent years. These coatings are specially formulated to minimize waste, remove harmful ingredients and reduce carbon footprint, in line with the growing global focus on environmental sustainability. The shift comes in response to the traditional coatings industry’s heavy reliance on volatile organic compounds (VOCs) and other harmful chemicals that cause pollution and pose health risks. The need to reduce the impact of human activities on the planet has spurred the development of sustainable coatings. These environmentally friendly coatings, such as waterborne coatings, are designed to meet the growing demand for environmentally friendly products in a variety of industries.

The Role of Sustainable Formulation:

Sustainable coatings are formulated to minimize waste, eliminate harmful ingredients, and reduce the carbon footprint of their production and disposal. They often combine bio-based solvents, natural pigments (vegetable oils and natural resins, etc.) and renewable materials, in line with the circular economy model. Making paints contain fewer harmful chemicals, making them safer for the environment and human health.

One of the key characteristics of sustainable coatings is their ability to reduce waste. Additionally, these coatings are designed to maintain or even enhance the functional benefits of traditional coatings, such as durability and protection against environmental abrasion. Additionally, sustainable coatings are often recyclable or biodegradable, further reducing their environmental impact.

Future Growth Trends:

As regulatory pressure increases and consumer preferences shift toward environmentally friendly products, demand for sustainable coatings is set to increase. As environmental awareness among businesses and consumers increases, sustainable coatings are expected to continue to gain popularity. Innovations in green chemistry may further improve the performance and cost-effectiveness of these coatings, making them viable alternatives in more applications. For example: Photocatalytic coatings can use light generated by sunlight or artificial light sources to degrade harmful gases and improve indoor and outdoor air quality.

Applicability:

Sustainable coatings are particularly suitable for industries and applications where environmental impact is a concern, including construction, automotive, consumer goods, packaging and aerospace. Their use not only helps reduce the environmental footprint of these industries, but also meets growing consumer demand for products that contribute to a healthier planet.

In summary, sustainable coatings represent a significant advance in coatings technology, providing a more environmentally friendly alternative to traditional coatings. Sustainable coatings will play a vital role in creating a more sustainable future by minimizing waste, removing harmful ingredients and reducing carbon footprints.

Coating Safety Technology

Background and Advocacy:

Reducing the harm caused by coatings to the human body has always been a key focus of the industry. There is growing awareness of the health risks associated with volatile organic compounds (VOCs) and other hazardous substances commonly found in Conventional Solvent-Based Coatings. This concern stems from growing awareness of the potential hazards traditional coatings can pose to human health, particularly the respiratory safety of customers, users and workers.

Volatile organic compounds (VOCs) and formaldehyde are naturally emitted from paints, varnishes, furniture, carpets, cleaning products and other building materials. Long-term exposure to these chemicals can cause serious health problems, including respiratory problems, skin irritations, and more serious illnesses such as cancer. The pursuit of safer coating technologies reflects a broader movement toward workplace safety and environmental sustainability.

The Role of Green Safety Technology:

Green safety technologies in coatings are designed to minimize or eliminate the use of harmful chemicals, thereby reducing the health risks associated with their application and use. These technologies span a range of strategies, including developing water-based coatings and High solids Coatings, using natural, non-toxic raw materials, and improving protective equipment and ventilation systems to protect workers during application.

Future Growth Trends:

Demand for safer coating options is expected to continue to grow, driven by tighter regulatory standards and growing consumer preference for environmentally friendly and healthy products. Innovations in green chemistry may lead to new materials and formulations that further reduce the health risks associated with coatings and make safer products more accessible and affordable. Paint developers are actively working to remove potentially harmful ingredients from their products and find safer alternatives. For example, many manufacturers are eliminating VOCs in their next-generation coatings. VOCs can increase your carbon footprint, contribute to air pollution, and cause health side effects such as respiratory irritation. The development of water-based coatings with low volatile organic compounds has received attention. This is a paint that contains fewer VOCs or VOC solvents than traditional paints. All this marks that the coatings industry has entered a period of change that focuses on sustainability and safety.

Applicability:

Green safety technologies are particularly important in areas where paint health risks are most apparent. These include the construction and renovation industries, automotive manufacturing and any field where workers are regularly exposed to coatings, such as furniture manufacturing and shipbuilding. In these areas, safer coatings not only protect workers, but also the end users who live and work in the spaces treated with these products.

The emphasis on “coating safety” through green safety technologies represents a significant shift in the coatings industry, prioritizing human health alongside performance and durability. By integrating green safety technologies to reduce the harmful effects of coatings on the human body, particularly in terms of respiratory safety, the industry can not only combat immediate health concerns but also contribute to a more sustainable and responsible approach to manufacturing and applying coatings. As this trend continues, compliance with high safety and environmental standards may become a standard expectation for all coatings, marking a new era in the industry’s evolution.

Heat-Resistant and Corrosion-Resistant Coating Technology

The realm of coatings is witnessing a significant shift towards materials that can withstand extreme conditions without degrading. The advent of heat-resistant and corrosion-resistant coating technology marks a pivotal development in enhancing the durability and longevity of various surfaces. This technology is not just a testament to human ingenuity but also addresses a growing need for materials that can maintain their integrity in harsh environments.

Background and Advocacy:

The push for heat-resistant and corrosion-resistant coatings has been fueled by the limitations observed in conventional coating technologies. Traditional coatings often fall short in environments that are subject to high temperatures, intense ultraviolet (UV) radiation, or corrosive chemicals. This inadequacy can lead to frequent maintenance requirements, increased costs, and the premature failure of protected materials. The demand for more resilient coatings emerged from industries where the performance of materials under extreme conditions is critical, such as aerospace, automotive, marine, and industrial sectors.

Role of Next-Generation Coatings:

Next-generation heat-resistant and corrosion-resistant coatings are designed to provide superior protection against temperature extremes, UV exposure, and corrosive agents. These coatings are formulated using advanced materials, such as ceramics, silicones, and epoxy resins, which offer enhanced thermal stability and chemical resistance. By shielding surfaces from heat and corrosion, these coatings extend the lifespan of materials, reduce maintenance costs, and ensure the safety and reliability of critical components in various applications.

Future Growth Trends:

The future of coating technology looks promising, with continued innovation focused on improving resistance to heat, UV rays, and corrosion. As industries strive for greater efficiency and sustainability, the demand for coatings that contribute to energy savings and environmental protection is expected to rise. Advances in nanotechnology and material science will likely lead to the development of coatings with even greater resilience and multifunctional capabilities, such as self-healing and self-cleaning properties.

Applicability:

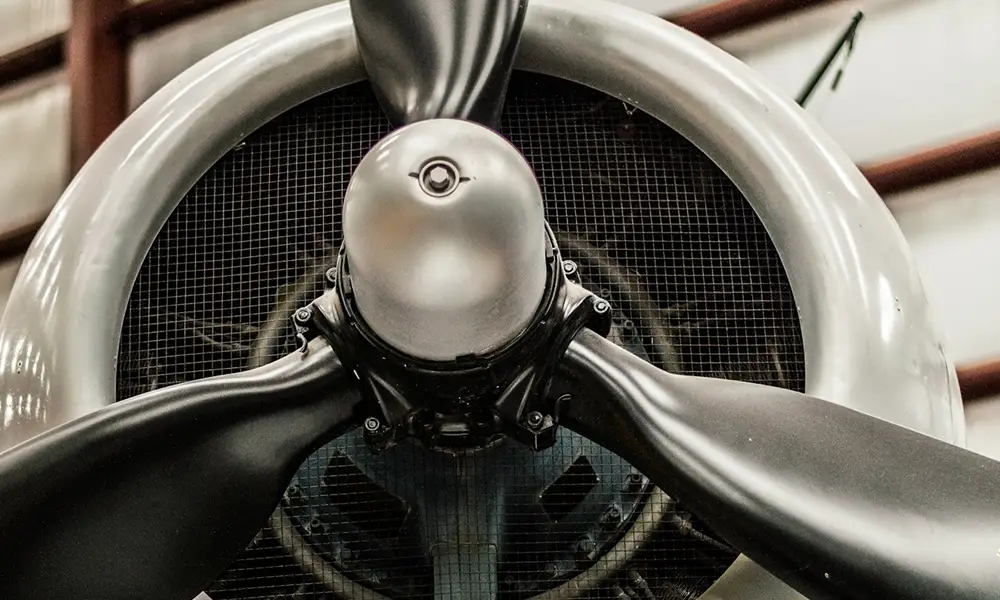

Heat-resistant and corrosion-resistant coatings have wide-ranging applications across numerous fields. In the aerospace industry, they are crucial for protecting aircraft components that are exposed to extreme temperatures and environmental conditions. In the automotive sector, these coatings enhance the durability and performance of engine parts and exteriors. Additionally, they are vital in the construction and marine industries, where materials are often exposed to harsh weather and corrosive elements. Furthermore, their application in renewable energy systems, such as solar panels and wind turbines, can significantly increase the efficiency and lifespan of these technologies.

The development of heat-resistant and corrosion-resistant coating technology represents a leap forward in our ability to protect and preserve materials in demanding environments. These coatings not only improve the quality of life by ensuring the durability and reliability of everyday products but also align with broader industry trends towards sustainability and efficiency. As we continue to push the boundaries of material science, the next generation of coatings will undoubtedly play a pivotal role in shaping the future of various industries, offering new possibilities for innovation and development.

Self-Cleaning Coating Technology

The concept of self-cleaning coating technology represents a significant advancement in the field of surface treatments and coatings. This innovative technology harnesses the power of waterproofing agents or nanoscale materials like titanium dioxide to create surfaces that automatically repel dirt, stains, and water, thereby remaining clean without the need for manual cleaning. This technology has not only captured the imagination of the industry but has also marked a turning point in how we approach surface cleanliness and maintenance.

Background and Advocacy:

The drive towards self-cleaning coatings emerged from a growing demand for low-maintenance and durable surface treatments capable of withstanding environmental pollutants and reducing the need for harsh cleaning chemicals. Urbanization and industrialization have significantly increased the levels of dirt and pollutants that buildings and vehicles are exposed to, necessitating frequent and often labor-intensive cleaning processes. The introduction of self-cleaning technology promised a solution to these challenges, offering a way to keep surfaces clean through innovative chemical and physical properties.

Role of Self-Cleaning Technologies:

Self-cleaning coatings work on two principal mechanisms: hydrophobic (water-repelling) and photocatalytic (light-activated) actions. Hydrophobic coatings utilize waterproofing agents to create a surface that repels water and oil, making it difficult for dirt and pollutants to adhere. Meanwhile, photocatalytic coatings use nanoscale titanium dioxide to react with natural or artificial light, breaking down organic pollutants and allowing them to be easily washed away by rain or minimal water contact. This dual approach not only keeps surfaces clean but also contributes to reducing water usage and the environmental impact of cleaning agents.

Future Growth Trends:

The self-cleaning coating market is poised for significant growth, driven by advancements in nanotechnology and increasing environmental awareness. Innovations in materials science are expected to lead to more efficient and affordable self-cleaning coatings, broadening their applicability across various sectors. Additionally, as the global emphasis on sustainability and environmental conservation continues to grow, the demand for eco-friendly and maintenance-reducing technologies like self-cleaning coatings is expected to rise. The self-cleaning hydrophobic coatings market is growing at a CAGR of 7.2%, and industry analysts expect the market to be worth over $3.5 billion by 2030, indicating strong market and user interest.

Applicability:

Self-cleaning coatings have a wide range of applications, from architectural surfaces like windows, facades, and roofs, to automotive windshields, solar panels, and even textiles. In the architectural sector, these coatings can significantly reduce maintenance costs and improve the longevity of building materials. For vehicles and solar panels, they ensure optimal performance by maintaining clean surfaces that enhance visibility and energy efficiency, respectively. The technology is also increasingly used in public infrastructure, such as bridges and monuments, to protect against environmental degradation and vandalism.

Self-cleaning coating technology is a game-changer in the quest for more sustainable and low-maintenance solutions across various industries. By leveraging the properties of waterproofing agents and nanomaterials like titanium dioxide, these coatings offer a practical and eco-friendly way to maintain cleanliness and integrity of surfaces. As research and development in this area continue to advance, we can expect to see broader adoption and further innovations that will solidify the role of self-cleaning coatings in the future of material science and surface treatment technologies.

Self-Healing Coating Technology

Self-healing coating technology represents one of the most innovative advancements in the field of materials science and coatings. This technology, particularly when enhanced with nano-self-healing functions, has the potential to significantly improve the durability and lifespan of various surfaces by automatically repairing scratches, thereby enhancing scratch resistance. Despite its promise, challenges such as cost, environmental impact, and compatibility issues with base materials have somewhat limited its widespread adoption. However, new methodologies in material dispersion within different resin chemistries are starting to overcome these barriers, heralding a more practical and effective use of self-healing coatings.

Background and Advocacy:

The interest in self-healing coating technology was sparked by the increasing demand for more durable, maintenance-free materials across various industries. Traditional coatings, while providing protection and aesthetic value, often fall short in terms of longevity and resistance to damage. Nano-self-healing coatings emerged as a solution to these limitations, offering the ability to automatically repair minor scratches and damages, thus extending the product’s life and maintaining its appearance without the need for manual touch-ups or repairs.

Role of Self-Healing Coating Technology:

At its core, self-healing coating technology utilizes micro or nano-sized capsules that contain a healing agent. When the coating is damaged, these capsules break open, releasing the agent which then reacts with the air or the coating itself to seal the scratch. This not only maintains the aesthetic appeal of the coated item but also protects it from further damage, such as corrosion or moisture ingress.

Challenges and Innovations:

The primary challenges hindering the mainstream adoption of self-healing coatings have been their high production costs, potential environmental impacts due to the materials used, and difficulties in achieving consistent integration with a wide range of base materials. However, recent innovations in the way these nano-materials are dispersed within different types of resin chemistries have begun to address these issues. Improved dispersion techniques are enhancing the compatibility of self-healing agents with various substrates, reducing costs, and mitigating environmental concerns by utilizing more eco-friendly materials.

Future Growth Trends:

The future of self-healing coating technology looks promising, with potential applications spanning across the automotive, aerospace, consumer electronics, and construction industries. These sectors stand to benefit significantly from coatings that can withstand everyday wear and tear while reducing maintenance needs and extending the lifespan of products. As research continues to advance, it is expected that self-healing coatings will become more affordable and environmentally friendly, paving the way for their integration into mainstream manufacturing processes.

Applicability:

Self-healing coatings are particularly suited for applications where durability and appearance are critical. In the automotive industry, for example, these coatings can significantly reduce the cost and time associated with repairing minor scratches and dents. Similarly, in the aerospace sector, the technology can help maintain the integrity of aircraft surfaces, contributing to safety and longevity. Consumer electronics and high-use surfaces in construction will also benefit from the enhanced protection and sustained aesthetic appeal provided by self-healing coatings.

Self-healing coating technology, especially when leveraging nano-self-healing functions, represents a significant leap forward in material science. By overcoming initial challenges related to cost, environmental impact, and compatibility, this technology is set to revolutionize how we protect and maintain a wide array of surfaces. As innovations continue to improve the performance and applicability of self-healing coatings, we can anticipate a future where materials can withstand the test of time more effectively, reducing waste and the need for frequent replacements.

Antibacterial Coating Technology

Antibacterial coating technology marks a significant advancement in the coatings industry, tailored to meet the increasing demand for hygienic surfaces in various environments. This innovative approach integrates antimicrobial agents into coatings to inhibit the growth of bacteria, mold, and mildew, thereby ensuring surfaces remain cleaner, fresher, and more durable over time. The application of such technology is especially beneficial in environments prone to microbial contamination, such as HVAC systems and ductwork, where microbial growth can cause severe damage and health risks.

Background and Advocacy:

Interest in antimicrobial coating technologies has surged as awareness of diseases caused by microorganisms and the need for cleaner public and private spaces have surged. Especially in 2020, the outbreak of the COVID-19 global pandemic has created an urgent need to maintain surface hygiene to prevent the spread of viruses and bacteria. Additionally, the increasing incidence of hospital-acquired infections (HAI) has prompted healthcare facilities to seek more effective solutions to create sterile environments. These factors, coupled with growing public concern about indoor air quality, have driven the development and application of antimicrobial coatings.

Role of Antibacterial Coatings:

The primary role of antibacterial coatings is to provide an additional layer of protection against microbial contamination on treated surfaces. By incorporating active antimicrobial agents into the coating formulation, these coatings can effectively prevent the growth and spread of harmful microorganisms. This not only contributes to a healthier environment by reducing the risk of disease transmission but also protects the integrity of the coated surfaces, extending their lifespan and reducing maintenance needs.

Future Growth Trends:

The demand for antibacterial coatings is expected to grow exponentially across various sectors, driven by an ongoing emphasis on health and hygiene. Innovations in coating technology are likely to yield more efficient and cost-effective solutions, broadening the scope of applications. The trend towards green chemistry and the development of environmentally friendly antimicrobial agents will further enhance the appeal of these coatings, aligning with the global push towards sustainability. The antimicrobial coatings market will grow at an annual rate of 11% in 2023 and is expected to be worth over $7 billion by 2027.

Applicability:

Antibacterial coating technology is highly versatile, applicable to a wide range of coatings including water-based, solvent-based, high-solids, and powder coatings. This makes it suitable for various fields, particularly:

- Healthcare facilities: To reduce the risk of HAIs by applying on medical equipment, walls, floors, and other high-touch areas.

- Public spaces and transportation: To ensure cleaner surfaces in areas with high foot traffic, such as schools, airports, and public transit systems.

- Food and beverage industry: To prevent biodegradation and contamination in food processing and storage areas.

- HVAC and ductwork systems: To protect against microbial growth that can compromise air quality and system efficiency.

Antibacterial coating technology represents a pivotal development in the pursuit of healthier living and working environments. By effectively inhibiting the growth of harmful microorganisms on treated surfaces, these coatings play a crucial role in preventing disease transmission and protecting infrastructure. As this technology continues to evolve and expand its applications, it is set to become an integral part of hygiene and maintenance protocols across industries, contributing to a safer and cleaner world.

Temperature Indicating Coating Technology

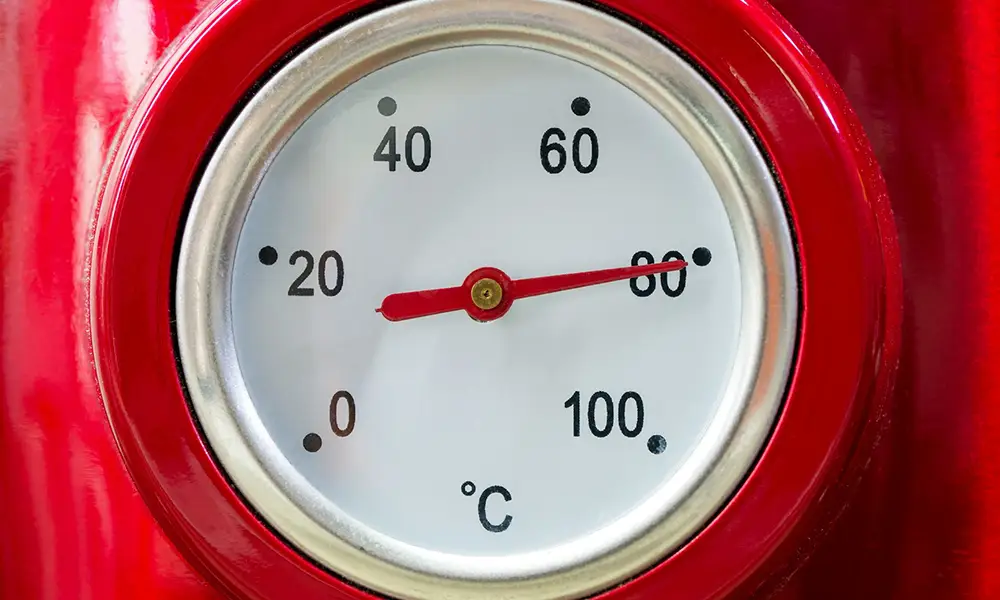

Temperature indicating coating technology represents an innovative approach to coatings, integrating metal and ceramic nanomaterials into paint matrices. These coatings change color or heat conduction properties in response to temperature variations, making them invaluable in applications requiring precise temperature monitoring and efficient heat transfer.

Background and Advocacy:

The interest in temperature indicating coating technology stems from the need for advanced materials that can provide real-time, visual feedback on temperature changes. This technology is particularly useful in industries where accurate temperature monitoring is critical, such as aerospace, automotive, and electronics manufacturing. The ability to detect temperature changes visually can help prevent overheating, optimize energy efficiency, and improve overall safety.

Role of Temperature Indicating Coatings:

Temperature indicating coatings play a vital role in enhancing safety and efficiency in various industries. By providing a visual indication of temperature changes, these coatings allow for quick identification of hotspots or abnormal temperature variations. This proactive approach helps prevent equipment failure, reduce energy consumption, and optimize processes that rely on precise temperature control.

Future Growth Trends:

The demand for temperature indicating coatings is expected to grow steadily, driven by advancements in nanotechnology and increasing emphasis on safety and efficiency. As industries continue to prioritize cost-effective solutions for temperature monitoring, these coatings will play an essential role in ensuring equipment reliability and process efficiency.

Applicability:

Temperature indicating coatings are particularly suitable for industries where precise temperature monitoring is critical, such as:

- Aerospace: Monitoring temperature changes in aircraft engines, thermal protection systems, and composite materials.

- Automotive: Detecting overheating in engines, exhaust systems, and braking systems.

- Electronics: Monitoring thermal management in electronic devices, circuit boards, and batteries.

- Energy: Optimizing heat transfer in solar panels, wind turbines, and power plants.

Temperature indicating coating technology represents a significant advancement in materials science, offering a practical and efficient solution for temperature monitoring in various industries. As this technology continues to evolve, it is expected to become a standard feature in many applications, enhancing safety, efficiency, and overall performance. Its ability to provide real-time, visual feedback on temperature changes makes it a valuable tool for optimizing processes and ensuring equipment reliability in a wide range of industries.

Solar Coating Technology

Solar coating technology, a promising innovation in the renewable energy sector, is garnering significant interest due to its potential to transform everyday surfaces into sources of clean energy. This technology involves integrating photosensitive particles into paint, allowing surfaces like roofs and walls to harness solar energy and convert it into electricity. While current solar coating technology may not match the efficiency of traditional solar panels, it can complement existing solar panel installations, maximizing clean energy generation.

Background and Advocacy:

The increasing focus on renewable energy sources, coupled with a growing emphasis on sustainability, has fueled interest in solar coating technology. As traditional energy sources become more limited and environmental concerns escalate, there is a pressing need for alternative, eco-friendly energy solutions. Solar coating technology offers a practical and innovative approach to harnessing solar energy, making it an attractive option for individuals and industries looking to reduce their carbon footprint.

Role of Solar Coating Technology:

Solar coating technology plays a crucial role in expanding the reach of solar energy generation. By enabling surfaces to function as solar panels, this technology diversifies the sources of clean energy and reduces reliance on traditional energy sources. Additionally, it allows for more flexible and creative integration of solar energy systems into buildings and infrastructure, paving the way for sustainable urban development and energy-efficient architecture.

Future Growth Trends:

The future of solar coating technology looks promising, with ongoing research and development aimed at enhancing efficiency and affordability. As advancements continue, we can expect to see improvements in the efficiency and durability of solar coatings, making them more competitive with traditional solar panels. This trend is likely to drive increased adoption of solar coating technology in various sectors, contributing to the global transition towards renewable energy sources.

Applicability:

Solar coating technology is particularly suitable for buildings and structures where traditional solar panels may not be feasible or aesthetically desirable. It can be integrated into architectural designs, such as windows, facades, and roofing materials, allowing for seamless integration of solar energy generation into the built environment. Additionally, solar coatings can be used in transportation, such as coating vehicles to generate electricity or improve fuel efficiency.

Solar coating technology represents a significant step towards achieving sustainable and clean energy solutions. While still evolving, this technology holds immense potential to transform how we generate and utilize solar energy. As research and development in this field continue to advance, we can anticipate a future where solar coatings play a pivotal role in our transition to a more sustainable and eco-friendly energy landscape.

What Obstacles Will We Face in Advancing New Coating Technologies?

Advancing new coating technologies is an exciting endeavor, but it comes with its share of challenges. Understanding these obstacles is key to overcoming them and ensuring the successful implementation of innovative solutions.

- Technology Research and Development:Developing new coating technologies requires significant research and development efforts. This process can be time-consuming and costly, as it involves experimenting with new materials, formulations, and application methods. Additionally, ensuring that these new technologies meet industry standards and regulations adds another layer of complexity.

- Cost:Cost is a significant barrier to the advancement of new coating technologies. Research, development, and implementation costs can be substantial, especially for small businesses or startups. Manufacturers must also consider the cost-effectiveness of new technologies compared to traditional methods to ensure their viability in the market.

- Safety and Environmental Sustainability:As the industry focuses more on sustainability, new coating technologies must meet stringent safety and environmental standards. This includes reducing or eliminating the use of harmful chemicals, minimizing waste, and ensuring that coatings are safe for both workers and the environment.

- Market Production Changes: Introducing new coating technologies can disrupt existing production processes. Manufacturers must carefully plan and implement these changes to minimize disruptions and ensure a smooth transition to new technologies. Additionally, educating consumers and contractors about the benefits of new technologies is crucial for their acceptance in the market.

- Risks of Unknown Factors: Finally, new coating technologies may bring unforeseen risks and challenges. These could include compatibility issues with existing materials, performance issues in different environments, or unforeseen health and safety concerns. Thorough testing and evaluation are essential to identify and mitigate these risks.

Overcoming these obstacles requires collaboration and innovation across the industry. By addressing these challenges head-on, we can advance new coating technologies that are safer, more sustainable, and more effective than ever before.

How to Improve the Innovation Ability of the Coatings Industry?

Improving the innovation capabilities of the coatings industry is critical to driving growth, competitiveness and sustainability. The following are some strategies that I personally feel can help achieve the goal of rapid and reliable innovation in coating products after working in the coatings industry for so long:

- Invest in Research and Development (R&D): Allocate resources to R&D efforts to explore new materials, technologies, and processes. Collaborate with research institutions, universities, and other industries to leverage expertise and resources.

- Embrace Digitalization and Data-Driven Approaches: Utilize digital technologies such as AI, machine learning, and data analytics to optimize processes, improve product performance, and develop innovative solutions.

- Focus on Sustainability: Develop eco-friendly coatings that reduce environmental impact, lower carbon footprint, and comply with regulations. Explore renewable and bio-based materials as alternatives to traditional ingredients.

- Enhance Collaboration: Foster partnerships and collaborations within the industry and across sectors. This can lead to the exchange of ideas, shared resources, and joint development projects that accelerate innovation.

- Customer-Centric Innovation: Understand customer needs and preferences to develop coatings that meet specific requirements. Engage with customers to gather feedback and insights that inform product development.

- Invest in Talent Development: Build a skilled workforce with expertise in coatings technology, chemistry, and engineering. Provide training and professional development opportunities to keep employees updated with the latest trends and technologies.

- Adopt Agile Development Practices: Implement agile methodologies to streamline product development processes, reduce time to market, and quickly respond to changing market demands.

- Open Innovation: Look beyond internal resources and collaborate with external partners, suppliers, and startups to access new ideas, technologies, and markets.

By implementing these strategies, the coatings industry can enhance its innovation capabilities, drive sustainable growth, and meet changing market demands. These are just my personal one-sided opinions and may not necessarily be in line with the actual situation of the entire industry. If you have a personal opinion or think there is anything that needs to be modified in the above content, please leave a message below.

As we conclude our tour of the world of coatings, we hope you gained valuable insights into the latest trends and technologies shaping the industry. When choosing paints and coatings suppliers, remember to take advantage of the filtering capabilities available on our website to find the reliable coatings supplier that best suits your needs. If you have any questions or unique insights about future coating development trends, please feel free to contact us or leave a message below for discussion.

What is the new technology in house paint?

Green antibacterial paint is currently the most popular new technology in house coatings.

Thanks to the latest innovations, coatings can now be combined with Titanium oxide nanoparticles. to eliminate any harmful microorganisms. Keeps walls germ-free while promoting self-cleaning of the air in the room

What is smart paint technology?

Smart coatings are designed to remain passive until their surface is stimulated by an external medium, activating their specific properties. Made by mixing a unique light-converting oxide into thermoplastic paint. For example, “temperature-indicating paint” is a representative product of smart paint: when the surface temperature of an object reaches the set value of “temperature-indicating paint”, it will be activated to display different colors.

What is nanotechnology in paint?

Nanotechnology in paint is like a sprinkle of magic powder that turns traditional paint into a superhero version. This advanced technology involves manipulating materials at the molecular level, typically below 100 nanometers. At such a tiny scale, even the most ordinary materials can exhibit amazing properties. Imagine a wall that cleans itself, or a car that rarely needs washing – thanks to nanotechnology, these are no longer just pipe dreams. The addition of nano silicon dioxide to paints can improve the macro- and micro-hardness, abrasion, scratch and weather resistance, color richness, and even antimicrobial properties. Nanotechnology extends the life and functionality of paint surfaces well beyond their usual limits.

What nanomaterials are used in paint?

When it comes to the role of nanomaterials in the ensemble, each plays a key role in improving coating performance. Nanomaterials often used in coatings include: nanosilver, photocatalytically active nanotitanium dioxide, nanozinc oxide or nanosilica.

Titanium dioxide and zinc oxide are shining stars for their role in sun protection, with UV-resistant properties that help prevent fading and material degradation. Silver nanoparticles have also emerged, providing a killing blow to bacteria and fungi, making surfaces cleaner and more hygienic. Then there are silica nanoparticles, which slip into the paint to enhance its scratch resistance, ensuring the surface can withstand the wear and tear of everyday life. Each of these nanomaterials works behind the scenes in paint to make the coatings on our walls and vehicles not only more beautiful, but also more functional and durable.