Have you ever noticed the outer shells of refrigerators in your home, the colorful steel roofs in the neighborhood, and the beautiful facades of modern buildings in your city? They’re all coated with beautiful paint right? But just try to imagine these are all done by people holding brushes and painting day and night. That’s way too troublesome and inefficient! As for this, coil coating absolutely plays a big role.

What Is Coil Coating?

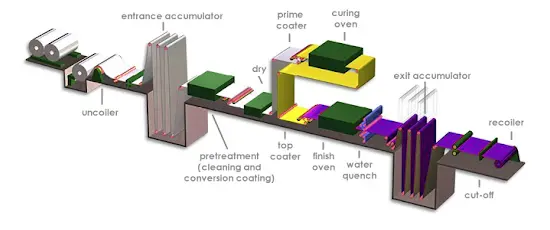

Coil coating is an automated process to produce high-quality coated finish before fabrication into final products. Its efficient production line which can run at speeds as high as 700 feet per minute without ever stopping or changing speed equips the material being coated with extremely consistent properties.

(source: NCCA)

This very refined process basically includes these following steps in common:

- 1) Unwinding and cleaning the coil (The steel or aluminum substrate is delivered in coil form from the rolling machines), if necessary.

- 2) Chemical pre-treatment of the metal surface( we can choose to do it on either one side or both sides). In this step, through chemical conversion (such as phosphating or chromating), a micron-level protective layer is formed on the metal surface that can significantly enhance the adhesion between the coating and the substrate and fundamentally improves corrosion resistance, laying a solid foundation for the subsequent flawless coating application.

- 3) Curing process: Application of liquid paints or coating powders which are subsequently heat cured or laminated with plastic films. This high-speed curing stage is the key to the coating’s performance success–The metal strip travels at speeds of hundreds of meters per minute through curing ovens that can be dozens of meters long, experiencing precisely controlled temperatures for a matter of seconds. During this process, the resins within the coating will be gradually transformed from a liquid state into a solid film.

- 4) Cooling and rewinding the same coil for shipment to a sheeter, a slitter or a fabricator. (Then for the fabricator, the processed coil will be cut to desired size and formed into its final shape.)

So, basically we can perceive this entire process a highly integrated closed-loop system. From uncoiling to recoiling, the production line operates continuously without interruption. This not only achieves extremely high production efficiency but also allows for volatile organic compounds (VOCs) to be centrally collected and efficiently treated (with removal rates exceeding 99%), perfectly demonstrating its dual advantages in both efficiency and environmental protection.

With this highly mechanized process, coil coating can be adaptively formed into a variety of colors, textures and shapes, while ensuring exceptional durability and weather resistance, guaranteeing an extended service life.

Major Innovation of Coil Coating

As a flourishing industry, there are many edge-cutting technologies behind this prepainted matel technique that strongly support its development. Here I’d like to demonstrate the main innovation of coil coating for you, from the aspect of efficiency and sustainability respectively.

Coil coating has involved a lot of techniques in the whole process to foster its productivity.

Roller coating, the basic yet essential technique of applying paint at the heart of pre-painted metal, is an indispensable part of allowing the production line to become faster, more consistent.

- Curing ovens is the most energy-intensive part of the coil coating process where several major tech improvements have taken place. The more and more efficient ovens are capable of curing paint within seconds using not only traditional gas-fired techniques, but also innovative induction like IR/NIR, UV/EB curing techniques.

- Coil coating technique nowadays has largely reduced water usage in its process by adopting a reverse-cascade rinsing and a no-rinse pre-treatment on coil coating lines.

- The coil coating process allows for very efficient collection of VOCs from the solvents used in paints and the latest oxidisers, ensuring that over 99% of these are destroyed without polluting the atmosphere. A convincing example is that, Ecca has achieved a reduction in energy consumption of 35% and has cut their fossil fuel-based CO2 emission by 50% since 2008.

How Big Is the Coil Coating Market?

There is no doubt that coil coating has become a powerful and thriving global sector nowadays(which has covered 1,407 million square meters in 2024 alone, wildly used in construction, automotive, and consumer goods).

Statistics from leading firms like Zion Market Research has shown that the market, valued at approximately $3.58 Billion in 2025, is projected to expand to $5.18 Billion by 2034. This represents a Compound Annual Growth Rate (CAGR) of 4.20%, convincing that the development of coil coating today is fueled not by hype, but by the concrete advantages it offers: superior efficiency, environmental compliance, and unmatched quality like durability and aesthetic flexibility that enables this industry to become even more valuable to manufacturers worldwide.

Regional Insights.

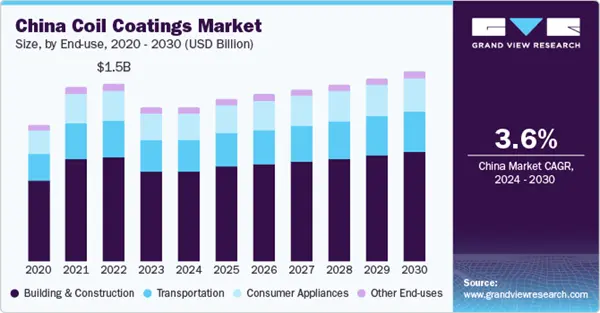

Asia-Pacific leads the Global Coil Coating Market with a revenue share of more than 70% in 2025, supported by large-scale infrastructure projects,automotive, rapid industrialization, increasing investments in housing and a surge in foreign investments, and high demand from emerging economies like China, India, and Southeast Asia, which subsequently propelling coil coatings demand in the region over the forecast period.

Among many developing countries in the Asia-Pacific area, China held the largest share of the coil coatings market in 2025. Since the shadow of COVID-19 gradually diminished in 2022, investors’ confidence has been positively influenced, accelerating ongoing projects in China. One convincing evidence is that there have been more than 20 active railway projects, with an additional 30 construction projects initiated since January 2023. These expanding industries have led to a spurt in the growth of the market in the country.

Cited from Grand View Research

The North America Coil coatings market is expected to grow significantly from 2024 to 2030. The emerging trend of pre-engineered buildings, where coated steel sheet is an important building material for roofing and exterior applications, is expected to remain a key promising area in the market.

In Europe, due to macroeconomic challenges, increased production expenses, a decline in demand for finished goods, and other factors, it has been adversely influenced in the steel production and consumption,making its fall from the second-largest regional market in 2023 to the third-largest in 2025. This situation has had a negative impact on the coil coating market within the region.

The coil coatings market in Central & South America is anticipated to witness significant growth from 2024 to 2030. The rising number of small- and medium-sized enterprises in Central & South America, along with the demand for industrial products, has boosted the construction of logistics, retail, commercial, distribution, transport, and agricultural facilities in the region.

What Types of Coil Coatings Are Available?

In this quite a prosperous industry, selecting the right coil coating isn’t just about picking a color; it’s a critical technical decision that determines the longevity, appearance, and performance of the final product. From harsh weather to daily wear and tear in your home, different environments demand different solutions. Except for environmental factors, the type of coil coating varies from product to product, too. So, what are the options?

Basically, there are two main types of coil coating: liquid paints and powder coatings. However, due to its perfectly meeting the demands of high-speed production lines and the requirement for coating uniformity, liquid paints, currently, liquid paints account for over 99% of the coil coating market, representing the dominant application.

Here are some information of several typical liquid paints:

| Ingredients | Polyesters | Plastisols | Fluorocarbons (e.g., PVDF) | Polyurethane |

|---|---|---|---|---|

| Function | Provides flexibility, exterior durability and physical properties | Provides excellent system exterior performance and pretty good flexibility | Provides desirable color performance, gloss performance and flexibility | Provides excellent abrasion resistance, hardness, and chemical resistance |

| Applications | Appliances, Furniture, Transportation | Construction, Transportation | Construction | Appliances, Furniture, Machinery |

- Polyester:

It is one of the most widely used coil coatings, prized for its excellent flexibility and adhesion. Normally it can be found in residential roofing and siding, appliance exteriors (like washing machine panels and refrigerator backs), and indoor furniture. - Plastisol:

Plastisol is normally applied in an extremely thick layer (up to 200 microns or more), creating a superior physical barrier. It has a soft tactile feel and offers excellent corrosion resistance, along with damping properties that can greatly reduce noise and vibration. Therefore, its common applications include metal roof tiles, automotive underbody shields, appliance partitions and components where sound dampening is critical.

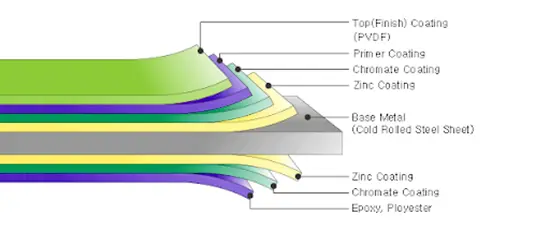

- Flourocarbons/PVDF:

It boasts exceptional weatherability and UV resistance, outstanding corrosion protection and superior color retention. While it comes at a higher cost, it offers the longest service life available.So from my perspective, this is the perfect choice for iconic commercial buildings, airports, and stadiums(often seen on their curtain walls and roofs).

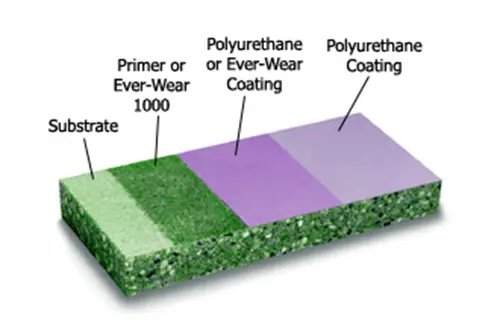

- Polyurethane:

This coating is renowned for its exceptional abrasion and scratch resistance, a hard surface finish, and a rich, luxurious appearance. With its extraordinary durability, I will consider it ideal for high-end appliances (e.g., oven front panels), construction equipment, container interiors, and any surface that requires frequent cleaning.

What are the ingredients for coil coating?

If you take a close look at a coil coating line, what you really find is not just paint but a carefully balanced recipe. Every high-performance system is built around four essentials – resins, pigments, solvents (or carriers) and additives. Each one plays a very different role, but the end result only works when they all come together during that split-second curing process on the moving strip.

- Resins, often called binders, are the backbone of the coating. They form the solid film and make it stick to the metal substrate. Swap one resin family for another and the performance changes completely. Polyesters are the all-rounders, combining flexibility and weather resistance. Fluoropolymers (PVDF) stand out for color retention and UV durability. Polyurethanes add hardness and chemical resistance. Plastisols (PVC-based) create thick, soft, noise-dampening layers. Epoxy systems are mostly used in primers to promote adhesion and corrosion resistance. Because coil lines run at hundreds of meters per minute and reach curing temperatures of more than 200 °C, these resins must crosslink fast yet remain elastic enough to survive later forming or bending.

- Pigments can provide color and hiding power, but their job usually goes further than looks. Inorganic pigments such as titanium dioxide, iron oxide or chromium oxide offer outstanding UV and heat stability, while organic pigments deliver bright, clean shades for interior or decorative uses. The pigment blend influences gloss, solar reflectance, and long-term weathering, which is why two panels of the same color can age differently if the pigment chemistry is not matched correctly.

- Solvents – or the carrier in high-solid and waterborne systems – are the temporary helpers. They adjust viscosity so the coating spreads evenly on the coil, then flash off in the oven, leaving a uniform, defect-free film. Modern coil coatings often use low-VOC or waterborne formulations to meet the environmental rules and reduce emissions, that is a major step forward compared with older solvent-heavy paints.

- Additives are the fine-tuning tools. They may account for only a few percent of the formula, but they control how the coating behaves during production and throughout its service life. Flow and leveling agents can prevent streaks or pinholes. UV absorbers and antioxidants can protect color and gloss. And the slip and abrasion modifiers improve cleanability and scratch resistance. In premium architectural or appliance systems, additives may even provide fingerprint resistance, heat reflectivity, or antibacterial protection. Other important additives also play roles, for example, catalysts that accelerate crosslinking reactions, surface modifiers that improve gloss or anti-fingerprint performance, and lubricants that reduce friction and enhance formability during the processing.

Together, these components turn a simple metal strip into a functional and long-lasting material. This balance greatly depends on where the product will be used, for example, building facades need maximum weather resistance, while home appliances call for the smoothness and chemical durability. In real-world production, even a small change in additive ratio can decide whether a panel bends cleanly or cracks at the corner, and that is why formulators carefully adjust every ingredient according to different applications and performance targets. In coil coating, chemistry is choreography that every element reacts in the perfect timing, under the right heat and speed, to produce a finish that looks more beautiful and lasts longer.

You know, coil coating really is far more than just painting metal. It’s a fast, precise and surprisingly clean way of giving steel and aluminum their final finish. What makes it stand out is the continuous line behind it – running non-stop, curing in seconds, and keeping the film perfectly even. At the same time, it manages to cut waste and VOC emissions, which is pretty impressive for an industrial process.

The numbers back that up too. The market keeps growing, especially in construction, appliances, and transport, where the demand for pre-finished metal just doesn’t slow down. Coil coating has already proved its value, and it’s clearly set to grow even further in the years ahead.

And honestly, as more companies chase greener production and faster turnaround, coil coating isn’t some future option anymore, and it’s happening now. If you’re part of this field, CoatingsDirectory is a good place to start: a space where makers, suppliers and buyers can find each other, share projects, and stay visible in this fast-moving industry.

FAQs

How is coil coating different from traditional spray painting?

Think of it as “pre-outfitting” the metal coil with its final finish in a factory, versus the traditional method of “tailoring and dressing” the final product piece by piece.

Coil coating applies paint to metal while it is still a continuous strip, in a fully automated, high-speed line. Traditional spray painting is done on finished, individual parts. This fundamental difference in sequence leads to vast improvements in efficiency, consistency, and environmental performance.

Why should I choose coil coating? What are the concrete advantages?

The core advantages can be summarized as less troublesome, cheaper yet faster, better and greener.

1. Save Cost: Lower total cost-in-use by eliminating expenses for in-house painting booths, labor, and waste disposal.

2. High Quality: Achieves unparalleled coating uniformity, free from runs, sags, or color mismatch.

3. High Efficiency: Production speeds can reach hundreds of meters per minute.

4. Eco-Friendly: Near-total paint utilization and captured VOC emissions make it a cleaner process.

How long does a typical coil coating project take from design to delivery?

For standard colors and materials, lead times can be short. However, for new custom projects, it typically takes several weeks.

This timeline includes formula development, lab testing, and scheduling a production run to ensure the coating meets all performance specifications.

Are there any certifications or standards of coil coating?

Yes, quality is guaranteed through rigorous international standards like QUALICOAT and GSB, which mandate strict testing for durability and performance.

Reliable suppliers adhere to these standards, which specify tests for adhesion, flexibility, salt spray resistance, and weatherability.

How environmentally friendly is the coil coating process?

It is one of the most sustainable metal finishing options available, significantly reducing waste and emissions compared to traditional painting.

The process is highly efficient: it captures and destroys over 99% of VOCs, uses water-efficient or no-rinse pretreatment systems, and achieves near-zero paint waste.