Industrial coatings aren’t just another line item on your project budget; they’re the invisible shield that determines whether your equipment lasts for years or fails prematurely. However, when you are faced with a list of possibilities, with varying price tags that are drastically different, it is simple to feel lost. Why should one coating be twice as expensive as another? Is the high-priced one worth it, or are you just paying for the brand name?

The thing is that the pricing is not random. It depends on the cost of raw materials, technical issues, environmental policies, and even the quantity you are ordering. Selecting the proper coating is not only about the price, but finding the right performance to suit your specific needs. The low-grade coating that peels off in half a year may cost you a fortune compared to a high-end product that will last ten years.

Throughout this guide, we will deconstruct the true cost driver of industrial coatings and, more importantly, how to make sense of the noise and choose the right one to suit your project. It makes a difference whether you are guarding steel beams against saltwater corrosion or ensuring that the factory floor can support heavy machinery; the correct option will save money, time, and headaches in the future. So, we will get your ideal coating for your next project.

What Factors Affect the Price Of Industrial Coatings?

Cost Factors for Industrial Coatings

The cost of industrial coating is not only based on the base material price: it is a complex formula in which surface preparation, environmental factors and weather predictions all have subliminal roles. By analyzing 142 unsuccessful coatings projects, we identified several key cost drivers: raw materials, formulation, labor, batch size, quality, and certification standards. These factors can help streamline budgeting and value-based purchasing. Let us unveil what suppliers do not always tell you up front.

- Raw Materials

In a paint company, raw materials may comprise 70 per cent of expenditures, depending on the coating technology. In more specialised and higher-performance coatings, raw material costs are lower as a percentage of costs. In the case of commoditised technologies, the costs of raw materials are an even greater proportion of prices. A toll paint company can use its buying power to offer cost savings on raw materials that it already purchases in large quantities for other customers. The large paint suppliers can buy solvents, resins (waterborne and solvent-borne), and other raw materials in bulk, and this can lead to savings of up to 50 per cent of the costs of raw materials to the customer. The other raw material saving opportunity is to check with your coatings supplier as to whether they have an alternative raw material that is a functional equivalent and is cheaper that can be substituted. - Coating Formulation

A paint expert might need to formulate some coatings depending on your request. As an illustration, in case you are asking a paint supplier to create a new product, the business will take a long time to come up with a solution. There are many different ways to approach the issue of formulating costs by paint manufacturers; some will bill by the hour, and some will offer a certain amount of initial help and then charge by the hour in the laboratory. Clearly, the longer it takes to come up with an acceptable formula, the greater the cost of developing or formulating.

Work with a paint manufacturer who has experience in coating chemistry or end-use applications you have the product developed to minimise formulating costs. And also, prior to sending your project to a formulator, you should note the most critical specifications and performance requirements of your coating, differentiating between the must-haves and the would-like-to-haves. The question you should ask yourself is: What does my customer really need for his end-use application? We have more than 50 years of experience in the manufacture of paints, and we understand that 10 per cent of a project can be done in 10 hours, but the last 10 per cent can take 200 hours. These costs can be minimised by figuring out what is most important before launching a formulation project. - Labour and Paint Manufacturing.

The more time it takes to produce a batch of paint, the higher the labour costs. These labour expenses will be added to your coating price. Typically, there is not a lot more work to make large batches than small batches. The time required in the manufacture of paint is largely determined by three factors which are namely: equipment, formula requirements and procedure, and manpower to complete the task. When a buyer purchases paint, he or she should ensure that the paint manufacturer has the best equipment and in-house expertise to produce a specific coating. One way to prevent being struck by the high cost of manufacturing is by visiting a prospective supplier and getting them to draw a clear picture of the kind of equipment your coating will be produced.

Other formulas, especially high viscosity formulas and pigmented coatings, have a nature that requires longer manufacturing time. Other raw materials are more demanding in terms of equipment, time, energy, and care to process than others. It can be time-consuming and complicated to match colours. In the event that your coating needs a colour match, make sure your paint supplier is familiar with colour development and matching. Ask your prospective supplier what he or she is comfortable matching to delta e. - Batch Size and Order Volume.

Your coatings manufacturer should have the right size mixing tanks, holding tanks, and other equipment to allow for optimal batch sizes and allow your coatings supplier to communicate the optimum processing volume to meet your needs. With that being said, generally, paint suppliers provide some sort of tiered pricing to incentivise larger order volumes. Larger volume batches reduce labour, prebatch, quality control, cleaning, and other costs per gallon. - Quality Control.

Industrial coatings manufacturers are advised to test their batches on viscosity, weight per gallon, dry time, gloss, colour, and pH at a minimum. Unless your coating needs only a minimal battery of quality control tests, this extra effort will find its way into your price. Quality control is a process that makes it reproducible in manufacturing and also gives you the same product. Make sure that your manufacturing partner is measuring all the properties that are relevant to your process. Your paint manufacturer ought to keep a record of all quality control adjustments, seek to identify trends in adjustments, and alter the formula or batch-making specification to guarantee the most efficient, precise and predictable manufacturing results. A retain and certificate of analysis of every batch should be retained by the coating manufacturers for an agreed time. - Environmental & Regulatory Compliance.

Stricter VOC (volatile organic compound) laws or hazardous material restrictions can force manufacturers to reformulate with costlier alternatives. Water-based coatings, for example, often carry a premium over solvent-based ones due to compliance costs. - Filling and Container Costs.

Paint manufacturers fill material into containers ranging from bulk tankards to one-ounce nail polish jars and everything in between. All else being equal, the larger the container, the cheaper it is per gallon to fill. This is both a function of how long it takes to fill and the cost of the container itself.CONTAINER FILLING & CONTAINER COSTS PER GALLON Tote (250-275G) Lowest Cost Drum (55G) Add $.50-$1.00 to tote fill Pail (5G) Add $2-3 to drum fill Single (1G) Add $3-5 to pail fill Plastic is usually less expensive than steel containers. Special lids and linings may also be expensive for their containers. When your product needs a special or specialised label, your paint manufacturer will also factor this into the price.

Cleaning Costs.

Cleaning machines that were used in the production of paint may lead to the formation of hazardous waste, and this is costly to the coatings manufacturers to dispose of. In case your paint needs solvent to clean up equipment once it has been manufactured, or needs a more thorough cleanup than usual, your coatings manufacturer will be adding that cost to your price. Inquire about the way your paint company reduces hazardous waste and cleaning expenses. A few common, effective ways to minimise hazardous waste generation include the use of a solvent still to turn solvents used in the paint manufacturing process into wash solvents and segregating and reusing tank washings for future batches of like solvents and colored systems.Inventorys.

Some coatings manufacturers will offer to hold finished goods inventory to shorten lead times on time-sensitive orders. The expense of storing these finished products in their warehouse is generally built into the price of the coating. Non-flammable coatings are easy to warehouse compared to flammable coatings which have to be stored with special sprinklers and other fire safety devices and have storage limitations.

As with anything in business, price drives many decisions during paint formulation and in choosing a paint supplier. It’s important for purchasing agents and product managers to understand the cost drivers that factor into pricing industrial coatings to arrive at a more informed paint supplier and product decision.

| FACTOR | EFFECT |

|---|---|

| Raw Materials | as much as 70% of cost, greater for commoditized products, less for specialized and high-performance technologies |

| Formulating | More formulating time, greater effect on price |

| Labor and Manufacturing | Greater manufacturing time and difficulty, higher price |

| Batch Size | Greater Batch Size, Lower Price |

| Order Volume | Greater Order Volume, Lower Price |

| Filling & Container | Larger Container Volume, Lower Price |

| Quality Control | More Extensive QC Requirements, Greater Price |

| Cleanup Costs | More intensive post-batch cleanup and/or hazardous waste generation, greater price |

| Lead Time | Shorter Lead Times, Greater Price |

| Finished Goods InventoryGreater Inventory Requirements, Greater Price |

How to Choose Industrial Coatings that Suit Your Needs?

Consider the equipment that you are coating today. In five years, it will have to contend with even worse weather, new regulations and tougher conditions. This was the lesson learned last summer by a factory in Texas, whose coating, supposedly standard, bubbled and peeled in a record heatwave, and they lost 3 weeks of production. In the meantime, a comparable plant with future-proof coatings did not skip a beat. The difference? One team chose coatings for today’s needs. The other is a preparation for the challenges of tomorrow. This is how you choose coatings that won’t disappoint when temperatures increase, and when regulations change. Here are some important factors to consider when choosing an industrial coatings that suit your needs.

Substrate Type: Matching Coating to Material.

It is important to check what a substrate is (its type) and what condition it is in (its shape) before choosing a coating. The two factors are important in the compatibility, performance and durability of coating.

Different coatings are needed on different materials. A coating system which is effective on steel might not be effective on concrete or aluminium. Every substrate, whether carbon steel, galvanised metal, stainless steel, aluminium, concrete or plastic composites, all possess different surface energy, porosity and preparation needs. An example is that concrete might need moisture-tolerant primers, whereas aluminium may need special etching or conversion coats to adhere. The compatibility of coating also relies on the exposure of the substrate to chemicals, thermal cycling and abrasion. A coating which is specific to your type of substrate gives you better adhesion, protection, and durability to begin with.

Substrate Condition: Assessing Corrosion and Existing Coating Integrity.

After determining the type of substrate, evaluate its condition, particularly when overcoating an existing system. Start with a visual examination to identify the degree and kind of rusting, which can be general, pinpoint, or spot rusting. This grouping assists in determining whether overcoating is possible or a complete removal and replacement is necessary.

Once the corrosion is determined, you can check how many coating layers there were, their thickness, and adhesion. The correct dry film thickness (DFT) measurements may be made with a Tooke gauge or magnetic pull-off equipment. Test in multiple locations- three tests per location (or more), and numerous locations in large structures such as tanks or bridges.

Also, test by adhesion (X-scribe and tape or knife adhesion tests). Check the delamination, cracking, or blistering. If these defects are extensive or severe, overcoating might not be recommended. Any findings must be recorded neatly, preferably on a building sketch or structural layout with test points clearly marked.

Testing Coating Adhesion To Ensure Reliable Overcoating.

It is imperative to understand the compressive load which the structure will sustain before a fresh overcoat is applied. The more layers of paint that are added, the more stress is placed on the current paint system. It is important to evaluate the capability of the structure to withstand this new stress without any negative consequences. The stress that is cohesively undergone by the structure differs with the kind of coating applied. Rigid conventional 2-component epoxies or aliphatic urethanes are more likely to experience higher cohesive stress on curing than more flexible paints such as acrylic emulsions. In whichever overcoat system is used, the thicker the film, the higher the cohesive stress. The assessment of the capacity of the structure to withstand this stress will help it be stable and endure in the long term.

Managing Cohesive Stress For Enhanced Coating Longevity.

Understanding the cohesive stress that the structure can endure is essential before applying a new overcoat. Adding additional layers of paint increases the cohesive stress on the existing paint system. It is crucial to assess whether the structure can handle this increased stress without adverse effects. The cohesive stress experienced by the structure varies depending on the type of coating used. Non-flexible conventional 2-component epoxies or aliphatic urethanes tend to develop higher cohesive stress upon curing compared to more flexible coatings like acrylic emulsions. Regardless of the overcoat system chosen, higher film thickness contributes to greater cohesive stress. Evaluating the structure’s ability to accommodate this stress ensures that it remains stable and durable over time.

Environmental and Operational Conditions.

Even the most superior coating system can be a failure in case it is applied in unsuitable conditions. Application environment is a key- but usually under-recognized- determinant of long-term performance. As an example, at temperatures below 50 o F (10 o C) standard epoxies will not cure correctly. Cold-cure amines, in such instances, are crucial so that the coating hardens as it should. Conversely, when faced with high humidity (more than 85 percent relative humidity), then moisture-tolerant polyureas are required to prevent curing problems and delamination.

The coating system performance is highly dependent on the geographic location as well as the exposure conditions. The buildings in Northern states with a more frequent freezing or snow environment are exposed to extra stress. In this instance the choice of low cohesive stress overcoat systems also becomes more critical in order to meet the harsh climate. Knowledge of the local environmental conditions will assist in selecting a coating system capable of resisting these conditions and offering long term protection.

Geometry counts, as well. Such complex shapes as pipes, tanks, or valves need special methods of coating, such as plural-component spray systems or electrodeposition, which enable an even coating of complex surfaces. Coatings used on field operations (e.g., in-place pipelines) prefer an extended pot life (e.g., longer than 60 minutes), whereas controlled shop environments can use fast-cure UV systems to provide quick turnaround.

Budget & Regulations.

The most appropriate coating not only refers to a good performance but should be financially and legally sound as well. A clever solution is lifecycle costing: rather than concentrating on initial price, look at the overall costs in the long term, such as surface preparation, labour, time lost during application, and waste disposal. As an example, high-solids paints (80%+) may save labour and material costs by as much as 30 per cent because fewer coats are required to obtain the required thickness.

Compliance with regulations is equally important. VOC limits (volatile organic compounds) exist in the U.S and are enforced by the EPA.- Waterborne coatings are easily able to comply with the 340 g/L requirement, but with reduced chemical resistance. A better alternative? High-solids solvent-borne epoxies, which are a blend of compliance and long-term durability. Materials also have to comply with such restrictions as the EU REACH regulation worldwide. Case in point, chromate-based primers are being replaced by cerium-modified, chromate-free systems. Likewise, the newer coatings are augmented with graphene-enhanced epoxies that are both performance and environmentally safe due to PFAS (forever chemicals) concerns.

Validation Protocol.

The question is, will it last after the coating is applied? That is where validation comes in. Begin with accelerated lab testing. Practical measures of performance are ASTM G154 (QUV exposure) in UV resistance and ASTM B117 in salt fog corrosion. Years of exposure outdoors can be estimated in a few weeks using these simulations.

However, lab tests are not sufficient. Supplement with real-life mockups- test panels coated and exposed on-site for 90 days can give you the vital information as to how a coating will perform in a real-life situation. Just as important is the person who applies the coating. In the case of a critical asset, such as offshore structures or chemical tanks, insist on NACE Level 2-certified applicators. This makes them aware of the particular handling and application requirements of high-performance coating.

Last, do not miss verification. Invite third-party inspectors to take measurements of dry film thickness (DFT) with ISO 19840-compliant gauges. Such independent audits are able to detect application bugs before they become multimillion-dollar failures.

Key Technical Parameters of Industrial Coatings.

Industrial coatings are important in protecting and improving the performance of surfaces that are subjected to severe environments, high wear or chemicals. Coatings have to satisfy certain technical parameters to be effective and these parameters determine the properties of the application, durability and industry standards. There are the factors of dry film thickness (DFT), VOC content, solids content, and gloss, which should, understanding these factors helps in selecting the right coating system and achieving optimal performance after proper coating application. These parameters directly affect not only the protective properties of the coating but also the facility and economy of application.

- Dry Film Thickness (DFT).

Dry Film Thickness (DFT) is the measurement of the coating’s thickness after it has fully dried and cured. It is expressed in microns (µm) or mils (1 mil = 25.4 µm) and is critical for evaluating whether a coating system will provide the intended protection. A coating with insufficient DFT may not provide adequate barrier protection, making the substrate vulnerable to corrosion, UV degradation, or mechanical wear. On the other hand, an excessive DFT can lead to issues like cracking, solvent entrapment, or sagging, compromising the coating’s performance and appearance. Proper control of DFT is essential in industrial settings, where specific standards must be met. Accurate application techniques and verification with DFT gauges ensure compliance and performance consistency. - Volatile Organic Compound (VOC) Content.

VOC content is the amount of volatile organic compounds emitted by a coating when it is being applied and cured. It is normally expressed in grams per liter (g/L) or pounds per gallon (lb/gal). VOCs are related with adverse environmental and health effects, including ground-level ozone and smog formation and risk to the safety of workers. Limits on VOC emissions are very strict in many countries and regions, and are critical to operating permits and environmental responsibility. Application-wise, high VOC paint can require special safety gear and ventilation. Alternatively, waterborne or powder coatings are being used more commonly, either low-VOC or zero-VOC, depending on the application, whether indoors or environmentally sensitive. The alternatives also usually come with less environmental impact. - Solids Content.

Solids content is the fraction of a coating left on the surface as a protective film after all the solvents have evaporated. The value is given as a percentage by weight or volume. A high solids coating deposits more material per unit of application, improving efficiency and coating coverage and also decreasing the number of coats necessary to reach a given DFT. There is also a general relationship between high solids and reduced VOC emissions, as there are fewer volatile constituents. Application-wise, high-solids coatings can be thicker and more viscous, and may need special equipment or application methods to apply uniformly. Their capacity to provide good protection with fewer coats can however save a lot of time and cost of labor in industrial areas. - Gloss.

Gloss is a measurement of the amount of light reflected off the surface of a coating, usually measured with a gloss meter at a certain angle e.g. 60 o or 85 o. It influences the aesthetics as well as the functional characteristics of the coating. High-gloss coatings give a glossy, reflective finish that may be aesthetically desirable, as well as easier to clean. They however have the tendency of emphasizing surface defects, and more intensive surface preparation is necessary. Conversely, low-gloss or matte finish provides a less flashy look and is more effective at hiding surface imperfections. Gloss may also be chosen in industrial settings due to functional considerations, including glare reduction or increased visibility in artificial lighting.

| Table Summary of Key Technical Parameters of Industrial Coatings | |||

|---|---|---|---|

| Parameter | Definition | Importance | Impact on Selection and Application |

| Dry Film Thickness (DFT) | Thickness of the coating after drying and curing | Ensures protection, durability, and compliance with standards | Must be controlled to avoid underperformance or defects; measured with specialised gauges |

| VOC Content | Amount of volatile organic compounds released during application | Influences environmental safety and regulatory compliance | Affects the choice of coating for health and environmental regulations; may require ventilation and PPE |

| Solids Content | Percentage of non-volatile material that forms the protective film | Determines efficiency, coverage, and VOC reduction | Impacts the number of coats needed, application methods, and overall cost |

| Gloss | Reflective quality of the coating surface | Affects appearance, cleanability, and light reflection | Influences surface preparation requirements and functional aesthetics (e.g., anti-glare, visibility) |

The selection of the appropriate coating system is a complex process that encompasses the assessment of the substrate, the current coatings, and the environmental factors. To guarantee that the chosen overcoat system provides satisfactory protection and durability in the long run, it is important to understand these factors. Our directory platform will help you find and connect with the suppliers or service providers who can contribute to your project. We will assist you in finding competent suppliers and seasoned service providers that can provide the expertise and assistance you need. Contact us today to search your options, compare capabilities and contact professionals who can offer specialised advice and technical assistance.

FAQs

What determines the cost of industrial coatings?

The level of effort and the amount of work/materials that go into coating solutions and coatings themselves will determine the price point that is set for these products and services. In case you desire high-quality work on a large portion of a custom solution, you can anticipate being charged higher.

How to choose the right industrial coating?

Industrial coatings cost is influenced by a number of factors, with the most important being the kind of coating, the size and complexity of the project, the surface preparation process, application process, and the cost of the material.

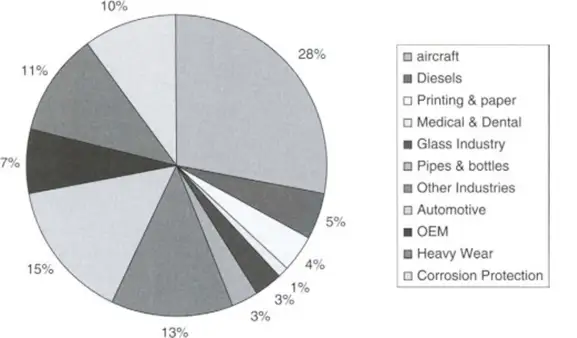

What industry is industrial coatings in?

The industrial coatings are also extensively applied in diverse end-use markets including automotive and vehicle refinishing, electronics, aerospace, oil and gas, mining, marine and power generation.

Who is the largest coating manufacturer in the world?

As the world’s largest paints and coatings company based on revenue, Sherwin-Williams is comprised of three segments: the Americas Group, Consumer Brands Group, and Performance Coatings Group.