Have you ever struggled to find that exact shade of paint? Or maybe a standard paint just didn’t hold up like you needed it to? Mixed paint is the exact thing you need. Instead of grabbing a pre-made can off the shelf, you can mix the components right before when you need it to get the best performance and color. It gives you amazing control over the final product, ensuring it’s perfectly suited for its job, whether that’s protecting a car, enhancing a home interior, or meeting tough industrial requirements.

This post dives into the world of mixed paint. Find out what goes into it, like resins and pigments. We’ll cover the big reasons why mixing paint yourself can be a great choice – from perfect color matching to getting the freshest possible product. Learn about different paint types, and touch on the important paint mixing standards that ensure quality and safety. Ready to see how mixed paint can truly hit the mark for your project?

What Is Mixed Paint?

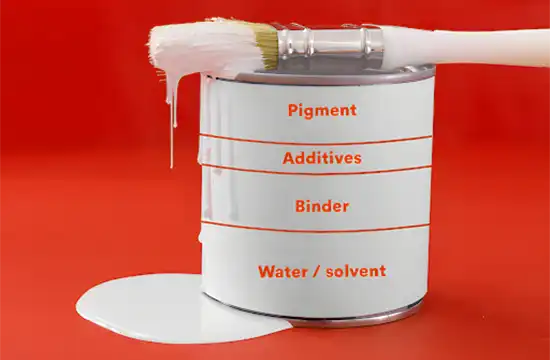

Essentially, mixing paint involves blending the components or colors of paint together to create a working material and achieve a desired hue or texture, rather than having it all done in a faraway factory. This allows for a high degree of customization. Imagine it like baking from scratch versus buying a pre-made cake – you control the ingredients. The main paint components are typically:

What Exactly Is Mixed Paint

- Resin (or Binder): This is the glue of the paint. It holds the color particles (pigments) together and makes the paint stick to the surface. The type of resin determines a lot about the paint’s final properties – like how tough it is or how well it resists sunlight. Common resins include acrylics (good flexibility, often used in house paints), epoxies (very strong, great for floors or industrial use), and alkyds (often found in oil-based paints). The right resin choice is key in any paint formulation.

- Pigment: These are the tiny, ground-up particles that give paint its color and hiding power (its ability to cover what’s underneath). Titanium dioxide is a super common white pigment that makes paint opaque. Other pigments create different colors – think iron oxides for earthy reds or blues from other compounds. Some pigments, called extenders (like clay or talc), add bulk or control the sheen without adding much color. Getting the right pigment mix is essential for color matching.

- Solvent: This is the liquid part that dissolves the resin and carries the pigment, making the paint flow so you can apply it easily. In water-based paints (often called latex paints), the main solvent is water – simple! In solvent-based paints, it might be mineral spirits, xylene, or other organic liquids. The solvent evaporates after you apply the paint, leaving the solid film behind. The choice of solvent affects drying time and application feel. Growing environmental concerns mean there’s a big push towards lower VOC limits (Volatile Organic Compounds), often found in solvents.

- Additives: These are like special ingredients added in small amounts to give the paint extra abilities. Think of things like driers to make oil paint dry faster, mildewcides to stop mold in damp areas, thickeners to stop drips, or UV stabilizers to protect against sun damage. Additives are crucial for fine-tuning performance in a custom paint mixing scenario.

By adjusting the amounts and types of these four core paint components, mixed paint lets you create coatings perfectly suited for specific jobs.

Why Mix Your Own Paint?

Okay, let’s talk about why custom paint mixing isn’t just for pros – it’s actually perfect for getting exactly what you need out of your projects. Forget those standard shades; mixing your own opens up a world of possibilities you just can’t get off the shelf.

- Get the Exact Color You Want (Precise Color Matching): This is often the biggest draw. Pre-mixed paints come in standard shades, but what if you need to match an existing wall perfectly, replicate a vintage car color, or create a unique artistic hue? Custom paint mixing allows for tiny adjustments using specific pigments to hit the exact color needed. Mix two colours to create something new or use white and black to make colours paler or darker. For artists or designers, this control is invaluable. Even in manufacturing, ensuring plastic and metal parts look the same color under different lights requires precise paint formulation and mixing. Tools like spectrophotometers can help measure color accurately for perfect color matching.

- Work with Fresh, Top-Performing Paint: Paint doesn’t last forever. Pre-mixed paint can sit on a shelf for months, and over time, its chemical properties can degrade. Pigments might settle, solvents can slowly evaporate, and additives might lose their punch. This can lead to problems like poor adhesion or uneven drying. When you mix paint fresh, you ensure all the paint components are at their peak performance. This means better results and potentially a longer-lasting finish. You also only mix what you need, reducing waste from old, unusable paint.

- Solve Tricky Application Problems: Different surfaces and painting methods need different paint properties. Spraying needs thinner paint than brushing. Painting smooth metal is different from painting porous wood. Temperature and humidity also play a role. Mixing your own paint lets you adjust the viscosity (thickness or thinness) using solvents or thinners. You can also add specific additives, like agents that help paint stick better to tricky surfaces or slow down drying on a hot day. This adaptability is key for professional results, especially with specialized coatings like an epoxy paint system.

- Save on Inventory Costs and Reduce Waste: If you do a lot of painting or handle varied projects, stocking dozens of different pre-mixed colors and types gets expensive and takes up space. With custom paint mixing, you can stock base materials (resins, common pigments, solvents, additives) and create the specific paint needed for each job. This means less money tied up in inventory. Plus, by mixing only the amount required, you drastically cut down on leftover paint waste, which is better for your wallet and the environment (less hazardous waste disposal).

- Customize Viscosity and Additives for Performance: This ties into solving application problems but goes further. Need a super tough floor coating? You might adjust an epoxy paint system formulation. Need extra grip on a painted walkway? You can incorporate anti-slip additives. Want a specific sheen, from dead flat to high gloss? Adjusting the binder-to-pigment ratio or using matting additives during mixing gives you that control. This level of fine-tuning performance with specific additives or viscosity adjustments is rarely possible with standard pre-mixed paints. Following proper paint mixing standards ensures these custom mixes work correctly.

Mixing paint yourself

Think about it, you aren’t stuck with a limited color palette. You can create virtually any shade you can imagine. This is great for matching existing finishes, bringing a unique design idea to life, or simply getting a color that truly feels like ‘you’. It’s about Color mixing to match your vision perfectly. Beyond just color, you can also tweak how the paint works. Need it to flow better for a spray gun? Want it to dry faster or slower? Adding specific components during paint mixing allows you to adjust things like viscosity, drying time, and final film properties, giving you the right paint for the job at hand. This kind of control ensures that colors match your vision perfectly and the paint performs just the way you need it to. Plus, it is more cost-effective than buying pre-mixed paint because you might end up buying not enough or wasting.

Types of Mixed Paint Systems.

Not all mixed paint is created equal, right? How it cures (that’s just a fancy way of saying “hardens”) and the liquid carrying the color pigment around actually tells you a lot about its type and where you should really be using it. Think of it like this: the materials basically break down into two main ways you can categorize these systems:

Single-Component vs. Two-Component Systems:

Single-Component vs. Two-Component Systems.

Looking at all those options, one of your first significant choices is whether you want a two-component system that calls for some prior chemical knowledge or something simple that you can just open and go, like a single-component system. Think of it like baking: sometimes you just use prepared cookie dough (your single component!), and other times you measure flour, sugar, and eggs to create something incredibly unique (your two components!). Choosing the ideal solution for your project calls for knowledge of these basic distinctions.

These are the simpler paint kinds. They arrive ready to use, perhaps requiring only a little stirring or thinning. Usually by the solvent (such water or mineral spirits) evaporating, or sometimes by reacting slowly with air, they heal physically. Consider some fundamental acrylic-epoxy floor paints or conventional latex wall paint (which are largely acrylic with a bit epoxy added for marketing).

- Pros: Easy to use, usually less expensive, decent shelf life.

- Cons: Usually less robust, less resistant to chemicals or severe wear than two-component systems. Ideal for light-duty zones.

These are the heavy hitters. They come in two separate containers – typically a base resin and a hardener (also called a catalyst or activator). You must mix these two parts together in a precise ratio right before application. This mixing starts a chemical reaction that causes the paint to cure into a very hard, durable film. The epoxy paint system is a classic example, widely used for tough jobs.

- Epoxy Paint System Example: An epoxy paint system usually combines an epoxy resin (like one based on bisphenol A) with a curing agent (like an amine or polyamide hardener). The specific hardener affects drying time, chemical resistance, and flexibility.

- Pros: Excellent durability, toughness, chemical resistance, and adhesion. Great for demanding environments like factory floors, garages (especially a 100% solids epoxy paint system), marine applications, or protecting steel.

- Cons: Requires accurate custom paint mixing (get the ratio wrong and it might not cure properly), has a limited “pot life” (working time after mixing), often more expensive, and can sometimes have issues like “amine blush” (a waxy surface layer) if conditions aren’t right. Following paint mixing standards for mixing ratios is crucial.

Solvent-Based vs. Water-Based Systems

Okay, so you’ve thought about whether you need a one-and-done or a two-part system. Now, let’s dive into what actually carries that paint goodness. This is where the classic showdown of solvent-based versus water-based comes in. Imagine you’re trying to dissolve something sticky – are you using water, or something stronger like nail polish remover? That’s essentially the difference here. The choice impacts everything from how easy it is to clean up your brushes to what fumes you’ll be dealing with, and even how tough the final finish is against different threats.

These dissolve the resin and pigments using organic solvents—such as mineral spirits, xylene, alcohol. Especially in tough industrial or outdoor uses, they often offer great flow, adhesion, and performance. For instance, solvent-based epoxies can be rather forgiving of oily surfaces.

But volatile organic compounds (VOCs) are its main drawback. These solvents evaporate into the atmosphere, therefore adding to air pollution and endangering applicators (who need appropriate ventilation and safety equipment). Leftover paint and cleaning supplies disposal is more difficult as well (hazardous waste). Environmental rules’ tighter VOC limits are especially reducing these for architectural applications.

These use water as the primary carrier. Modern water-based paints (like acrylic latex or waterborne epoxies) have improved dramatically. They use resins designed to be dispersed or emulsified in water.

Their main advantage is that they have very low or even zero VOC content, which makes them friendlier to the environment and safer for construction workers. Cleanup is usually easier (soap and water). They meet strict VOC limits. Advances mean their performance, durability, and chemical resistance are getting closer to solvent-based options, making them suitable for many residential, commercial, and even some industrial uses (like a water-based epoxy paint system for a warehouse floor). They might, however, be more sensitive to drying conditions (high humidity can slow things down) and may not yet match the absolute toughness of high-end solvent or 100% solids systems in extreme environments.

The trend is clearly moving towards water-based and high-solids (like 100% solids epoxy paint system) coatings due to environmental regulations and health concerns. However, the specific needs of the project – durability, application conditions, cost – will determine the best paint formulation and system type. Click here to see more blogs on shopping for mixed paint and cost analysis.

Industry Standards and Specifications for Mixed Paint.

Ever poured paint into a bucket, stirred it up, and just hoped for the best? While that might work for a quick touch-up, when you’re tackling bigger projects, especially in professional or industrial settings, ignoring the ‘how-to’ can lead to a real mess. We’re talking peeling finishes that don’t last, colors that don’t match, and even failing inspections because you didn’t meet local environmental rules. Getting great results with mixed paint isn’t just about throwing components together; it’s about following the map. There’s a whole world of industry paint mixing standards and specifications out there, designed to make sure your hard work pays off with quality, safety, performance, and environmental compliance. These aren’t just dusty rulebooks – they’re your guide to avoiding costly mistakes, covering everything from how paint is made to how it’s applied and tested. So, who sets these crucial guidelines?

Standard grades of mixed paint

- ASTM International: This group creates a vast number of technical standards, including many for paints and coatings. They have specific test methods for things like checking if resins and solvents are compatible (to prevent paint separating), measuring viscosity, or testing the durability of protective coatings. Adhering to ASTM methods helps ensure consistent quality in paint formulation.

- ISO (International Organization for Standardization): ISO provides globally recognized standards. For paint, they cover areas like testing paint particles, methods for determining viscosity, and guidelines for protective coatings on structures like steel bridges (ISO 12944 is widely used). Using ISO standards helps ensure products meet international benchmarks.

- PCA (Painting Contractors Association): Focused more on the application side, PCA standards define what a “properly painted surface” should look like – uniform appearance, no drips, proper hiding, etc. They set practical benchmarks for quality workmanship that contractors and clients can agree on.

- Green Seal: This organization sets environmental standards (like GS-11) for paints and coatings. They focus on criteria like low VOC limits (often aligning with strict regulations like California’s CARB rules), restricting toxic ingredients, and requiring performance testing. Choosing Green Seal certified products helps ensure a lower environmental impact.

- OSHA (Occupational Safety and Health Administration): Safety is paramount when dealing with paint components, especially solvents. OSHA sets rules for things like required ventilation in mixing areas, use of respirators when spraying toxic materials, and precautions against fire hazards (like using non-sparking tools around flammable solvents). These paint mixing standards protect workers.

Beyond these organizations, groups like SSPC (Society for Protective Coatings) define standards for surface preparation (critical for paint adhesion), while NFPA (National Fire Protection Association) sets fire safety codes for handling flammable paint materials.

Why Standards Matter for Mixed Paint?

- Consistency: Standards ensure that whether you’re doing custom paint mixing or using a pre-made batch, the properties (like color, viscosity, durability) meet defined criteria.

- Safety: Handling solvents and chemicals requires strict safety protocols, guided by OSHA and NFPA standards.

- Performance: Testing standards (from ASTM, ISO) verify that the paint, including specialized types like an epoxy paint system, will perform as expected under specific conditions (e.g., resist corrosion, adhere properly).

- Environmental Compliance: Standards like Green Seal and regulations setting VOC limits drive the industry towards more sustainable paint formulation and practices.

Whether it’s ensuring the right surface preparation for an industrial epoxy paint system or verifying the color matching of an architectural coating, these paint mixing standards provide the necessary quality control.

Mastering custom paint mixing by knowing components, advantages, and industry standards like ASTM, ISO, and PCA helps you to obtain exact colors and customized performance for any project. Whether it’s a single-component or two-component system, we’ve looked at the benefits of obtaining the precise paint you need, guaranteeing freshness, cost savings, and improved qualities. Understanding these elements enables you to choose wisely for excellent, long-lasting outcomes.

Ready to investigate the options for your upcoming project using bespoke paint? Here at coatingsdirectory.com, discover reliable paint suppliers or expert paint mixing services catered to your particular requirements. Should you have inquiries on paint mixing or wish to discuss your own unique color encounters, kindly comment below.

FAQs

Why is custom paint mixing better for color?

Custom paint mixing provides unmatched precision for getting the exact shade you need. It allows for fine adjustments to perfectly match existing colors or create unique hues, overcoming the limitations and potential batch variations found in pre-mixed paints.

What's special about an epoxy paint system?

An epoxy paint system is a durable two-component coating requiring mixing a resin and hardener before use. This chemical curing process creates a very hard, chemical-resistant finish ideal for demanding applications like garage floors, industrial settings, and protective coatings.

Are there rules for mixing paint (paint mixing standards)?

Yes, industry paint mixing standards (from groups like ASTM, ISO, PCA) guide quality, safety, and testing. These standards cover aspects like component compatibility, viscosity, application quality, worker safety (OSHA rules), and environmental limits (like VOC limits via Green Seal).

Is water-based mixed paint as good as solvent-based?

Water-based paint types are much better for the environment due to low VOC limits and are getting very good performance-wise. While high-end solvent or 100% solids systems might still edge them out in extreme conditions, modern water-based options offer excellent durability for many applications.