Metallic Paint and Metal Paint are often confused, but they serve different purposes and offer unique benefits depending on the project. Choosing between Metallic Paint and Metal Paint can be difficult if the differences and ideal uses are unclear. Today, CoatingsDirectory will walk you through their specific applications, advantages, and disadvantages. In addition, we will guide you through the key considerations for choosing the best type of coating for metal surfaces, whether it is a protective polymer coating or a decorative coating. We will also explore the types of polymer coatings suitable for metal surfaces, ensuring that you understand all options before making a decision. With this information, you will be able to choose the best coating to achieve the desired look and performance.

What is metallic paint?

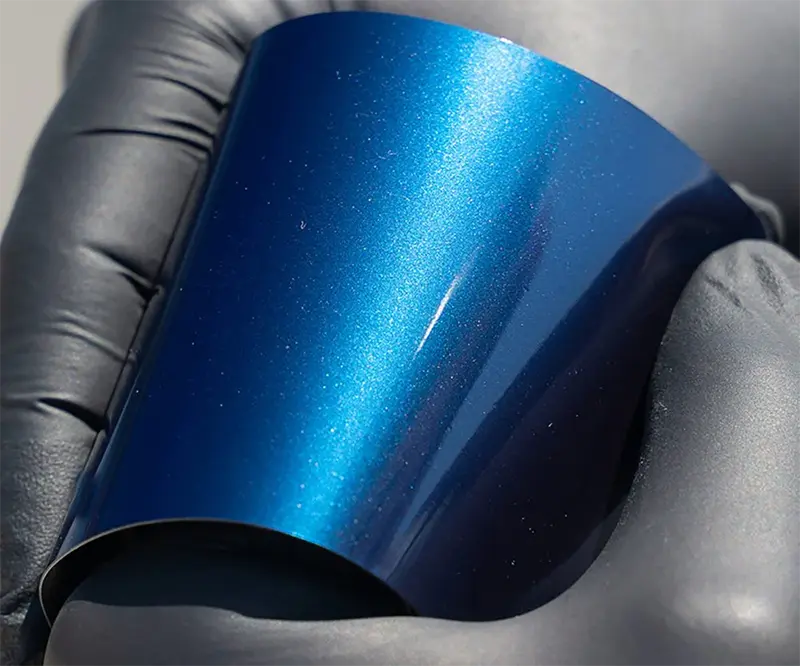

Metallic paint, also known as multicolor paint, metal flake paint or pearlescent paint, is a specialty paint that contains metal particles (usually aluminum or mica). These particles are suspended in the paint to create a finish that reflects light in a variety of ways, creating a shimmering metallic effect. Depending on the size and concentration of the metal particles, the final finish can range from shimmer, glitter, sequins, pearlescent, silver, bronze, gold or a highly reflective surface. Compared to standard non-metallic paints, the surface looks more vivid and dynamic, often enhancing the depth and richness of the color.

Metallic paint application sample display

Unlike traditional paints with flat or matte effects, metallic paints are designed to provide visual appeal and functional benefits. Metallic particles capture and reflect light, creating a multi-dimensional appearance that changes depending on viewing angle and lighting conditions. This play of light and color can make objects appear larger, more sculptural or more delicate. In addition, the clear coat that often comes with metallic paints helps protect the surface from UV rays, oxidation and minor wear and tear, making it a durable choice for many applications. Metallic paints have the following key characteristics:

- Reflectivity: The most distinctive feature of metallic paint is its ability to reflect light. The metal particles within the paint catch and reflect light in different directions, creating a sparkling effect that changes based on the light source and viewing angle.

- Depth and Texture: Unlike standard paints, metallic paint provides a greater sense of depth and texture. The metallic flakes add dimension, making surfaces appear more dynamic and three-dimensional.

- Durability: Metallic paints are generally more durable than standard paints, as they often come with a clear topcoat that provides additional protection against UV rays, scratches, and environmental damage.

- Color Variety: Available in a wide range of colors, metallic paint can be customized to achieve different finishes, from a subtle metallic sheen to a bold, glittery effect.

| Advantages and Disadvantages of Metallic Paint | |

|---|---|

| Advantages | Disadvantages |

| Creates a reflective, eye-catching finish that enhances visual appeal. | Metallic paint is generally more expensive than standard paint options. |

| Hides minor surface imperfections due to its reflective properties. | Requires skilled application to achieve a uniform finish. |

| Offers improved durability with resistance to UV rays and scratches. | More challenging to repair or touch up if damaged. |

| Available in a wide range of colors and customizable finishes. | May require additional protective clear coat for maximum durability. |

Due to the smooth, reflective sheen that metallic paint has when it dries, metallic paint is very versatile and can be used on most surfaces or projects.

- Automotive Industry: Metallic paint is widely used in automotive finishing to give it a unique, high-end look, especially for luxury and sports cars. The reflective properties of metallic paint help to hide minor scratches and dents, thus maintaining the visual appeal of the vehicle for a long time.

- Interior Design:In interior spaces, metallic paint can be used to add drama and elegance to walls, ceilings, furniture, and decor. It can be used to highlight architectural details or create feature walls that attract attention with a shimmering effect. It is common in luxury spaces, offices, and high-end businesses. It can provide a whole new look to any project or home renovation.

- Arts and Crafts: Artists and craftsmen use metallic paint to add unique effects to their projects. Its reflective properties are perfect for adding embellishments or creating textures on materials such as canvas, wood, metal, and ceramics.

- Industrial and Protective Coatings:Metallic paint is also used in industrial applications to provide aesthetic and functional benefits. For example, it is applied to machinery, tools, and equipment to enhance the appearance while providing resistance to abrasion and the environment.

Earlier we explored what metallic paint is, its unique properties, and the various applications in which it is a popular choice across industries. Now, let’s look at what gives metallic paint its unique look and durability—the materials and ingredients that make it stand out.

The unique properties of metallic paint come from a carefully balanced combination of ingredients. Each ingredient plays a specific role, from providing the paint’s reflective qualities to ensuring its durability and ease of application. These metallic pigments can be combined with opaque or translucent pigments in the paint base to form a coating. There are many types of coatings in the original metallic paint manufacturing, and some metallic coatings are applied as dry powders, electrostatically cling to the surface, and melt into a solid coating through a baking process. Let’s take a look at the key materials and ingredients commonly found in metallic paints:

- Metallic Pigments:

The primary ingredient that sets metallic paint apart from other types of paint is its metallic pigments. These pigments are typically tiny flakes of aluminum or other metals like bronze or mica. The flakes are ground to different sizes to create varying levels of reflectivity and texture. Larger flakes produce a more pronounced sparkle effect, while smaller flakes create a subtler sheen. These metallic particles reflect light, giving the paint its signature glittering appearance. - Binder or Resin:

The binder, often made of acrylic, polyurethane, or epoxy resins, is another essential component of metallic paint. It acts as the “glue” that holds the metallic pigments together and adheres them to the surface being painted. The type of resin used in the paint formulation can significantly affect the paint’s durability, flexibility, and resistance to UV radiation, chemicals, and environmental wear. High-quality binders are crucial for maintaining the paint’s appearance and performance over time. - Solvents:

Solvents are used to adjust the viscosity of the paint, making it easier to apply and ensuring a smooth, even coat. In metallic paint, solvents help dissolve the binder and create a uniform suspension of metallic flakes. Common solvents in metallic paints include water (for water-based paints), toluene, xylene, and mineral spirits (for solvent-based paints). The choice of solvent can influence drying time, finish quality, and ease of application. - Additives:

To enhance performance, metallic paints often include various additives. These may include:

Leveling Agents: Ensure a smooth surface by minimizing brush marks or roller streaks.

Anti-Settling Agents: Prevent the metallic particles from settling at the bottom of the can, ensuring an even distribution throughout the paint.

UV Stabilizers: Protect the paint from fading or yellowing when exposed to sunlight.

Corrosion Inhibitors: Prevent rust or degradation on metallic substrates. - Colorants:

While metallic flakes provide the reflective quality, colorants give metallic paint its base color. These are usually inorganic pigments, such as iron oxides, titanium dioxide, or carbon black, which are stable and resistant to UV light. The combination of these colorants with metallic flakes creates the desired hue and enhances the overall aesthetic appeal.

Metallic paint is much more than just a shiny finish—it’s a carefully formulated blend of pigments, binders, solvents, additives, and colorants, each playing a specific role in creating the paint’s unique properties. By understanding these materials and ingredients, you can better appreciate why metallic paint offers such distinct advantages in both aesthetic appeal and functional performance. Whether you’re in the market for a new automotive finish, planning a home renovation, or selecting coatings for industrial use, knowing what goes into metallic paint can guide you in choosing the right product for your needs.

What is the difference between Metal paint and Metallic paint?

When it comes to paint, the terms “metal paint” and “metallic paint” may sound similar, but they refer to two very different types of coatings, each with its own properties, applications, and benefits. Let’s take a closer look at how these two types of paint differ in terms of their uses, ingredients, finishes, durability, weathering, and maintenance requirements.

metallic paint vs metal paint

Purpose and Intended Use:

- Metal Paint: Metal paint is primarily designed for protective purposes. It is formulated to coat metal surfaces, such as iron, steel, or aluminum, providing a barrier against rust, corrosion, and environmental damage. The main goal is to protect the underlying metal and extend its lifespan, making metal paint ideal for both indoor and outdoor metal structures, like fences, gates, machinery, and vehicles.

- Metallic Paint: Metallic paint, in contrast, is intended for decorative use. Its primary purpose is to enhance the appearance of a surface by creating a shimmering, reflective effect. The metallic particles in the paint catch and reflect light, adding depth and a sense of luxury to surfaces. This type of paint is often used on vehicles, interior walls, furniture, and other objects where a visually striking finish is desired.

Composition and Finish:

- Metal Paint: Metal paint is composed of resins, binders, pigments, and additives like anti-corrosive agents. These components provide a durable, tightly adhering layer to metal surfaces. The finish is typically matte or semi-gloss, depending on the formulation, and focuses more on protection rather than appearance.

- Metallic Paint: Metallic paint contains fine particles of metal, such as aluminum or mica, suspended within the paint mixture. These particles are responsible for its characteristic shine and reflective qualities. The finish is usually high-gloss and reflective, enhancing the aesthetic appeal of the painted surface.

Durability:

- Metal Paint: Known for its high durability, metal paint provides excellent resistance to moisture, UV radiation, and other environmental factors. It is specifically formulated to prevent rust and corrosion, which is critical for maintaining the structural integrity of metal surfaces exposed to harsh conditions.

- Metallic Paint: While metallic paint is also durable, its primary strength lies in its aesthetic appeal rather than its protective properties. It typically requires a clear topcoat to protect the metallic particles and maintain its finish over time. Without this additional protective layer, metallic paint may be more prone to fading, chipping, or damage from the elements.

Weather Resistance:

- Metal Paint: Offers superior weather resistance due to its anti-corrosive properties and strong adhesion to metal surfaces. It is designed to withstand rain, humidity, and extreme temperatures, making it suitable for outdoor applications and environments with fluctuating weather conditions.

- Metallic Paint: Provides some degree of weather resistance, especially when applied with a protective topcoat. However, it is generally less resistant to weather compared to metal paint and may require more frequent maintenance to preserve its reflective finish.

Maintenance Requirements:

- Metal Paint: Low-maintenance, designed to protect metal surfaces with minimal upkeep. Occasional cleaning is usually sufficient to maintain its protective qualities and appearance over time. View a more comprehensive guide to using metal paint.

- Metallic Paint: Requires more maintenance to keep its decorative finish intact. Regular cleaning, polishing, and reapplication of a clear topcoat may be necessary to prevent oxidation and maintain its reflective properties.

| Aspect | Metal Paint | Metallic Paint |

|---|---|---|

| Purpose | Protective coating for metal surfaces | Decorative finish for aesthetic enhancement |

| Composition | Resins, binders, pigments, and anti-corrosive additives | Paint mixed with metal or mica particles for reflectivity |

| Finish | Matte or semi-gloss, focused on protection | High-gloss, shiny, and reflective for visual appeal |

| Durability | High, designed to withstand rust and environmental damage | Moderate; depends on clear topcoat for durability |

| Weather Resistance | Excellent; resists moisture, UV radiation, and temperature | Moderate; requires protective topcoat to resist weather |

| Maintenance | Low; minimal upkeep required | High; regular cleaning and polishing needed to maintain finish |

| Application | Applied directly to metal to prevent rust and corrosion | Applied to various surfaces for aesthetic enhancement |

| Common Uses | Industrial, automotive, outdoor metal structures | Automotive finishes, interior decor, art, and furniture |

How to Choose Between Metallic Paint and Metal Paint?

We have learned the difference between Metallic Paint and Metal Paint. Choosing the right paint for your project can be challenging, and while both offer unique benefits, the key is to match the paint type to your specific needs. Here, we list some factors to consider when choosing between metallic paint and metal paint, including application surface, environment, desired effect and maintenance requirements. Helping you get a clear understanding of which paint is best for your project.

- Application Surface

The type of surface you’re working with plays a significant role in determining which paint is most appropriate:

Metal Paint is suitable for metal surfaces such as iron, steel, and aluminum. It’s specifically designed to bond well with these materials and provide a strong, long-lasting protective layer. For example, if you are painting a wrought iron fence, a metal roof, or industrial machinery, metal paint is the go-to choice due to its anti-corrosive properties and superior adhesion.

While metallic paint can be applied to various surfaces (wood, plastic, metal, drywall), it is primarily used where an aesthetic, shiny finish is desired. For instance, if you are repainting the hood of a car, creating a statement wall in a living room, or refurbishing furniture for a more modern look, metallic paint will provide the dazzling, reflective effect you need.

- Environmental Conditions

The environment where the paint will be applied greatly impacts your choice:

If your project involves exposure to harsh outdoor conditions, such as rain, humidity, UV radiation, or fluctuating temperatures, metal paint is the better option. It is formulated to withstand these elements, protecting metal surfaces from rust, corrosion, and other environmental damages. An example scenario would be painting a metal railing or a gate exposed to all weather conditions; metal paint will offer superior protection and longevity.

Metallic Paint is best suited for controlled or indoor environments where the main purpose is to enhance the appearance rather than protect against extreme weather. It works well for indoor walls, decorative pieces, and interior automotive finishes. For example, a designer might use metallic paint to give a luxurious feel to a feature wall in a boutique hotel, where exposure to moisture and sunlight is minimal. - Desired Effect

Think about the visual outcome you want to achieve:

Metal Paint focuses on a functional finish with more matte or semi-gloss effects. It’s not intended for decoration but rather for practicality and protection. If your goal is to protect metal surfaces from rust while maintaining a subtle appearance, metal paint will deliver the result you need. Consider using it for a backyard shed or an industrial staircase where the look is secondary to durability and resistance.

Metallic Paint is designed for decorative effects and has a high-gloss, reflective surface that changes with light and viewing angle. It’s ideal if you want to create an eye-catching look. For example, using metallic paint on a car’s body can add a sleek, polished appearance that stands out. Similarly, adding metallic paint to a set of wooden chairs can turn a plain piece of furniture into a stylish statement piece. - Maintenance Requirements

Consider how much maintenance you are willing to commit to:

Metal Paint requires little maintenance once applied. Its protective properties mean that a single coat or two, in most cases, will keep metal surfaces safe for years without needing frequent touch-ups. This makes it ideal for applications where long-term durability is key, such as factory equipment or outdoor metal structures.

Metallic Paint may require more regular maintenance to maintain its aesthetic qualities. The reflective, glossy finish of metallic paint can lose its luster over time without proper care. For instance, a metallic-painted wall may require occasional cleaning and a topcoat refresh every few years to maintain its shine, especially in high-traffic areas. - Cost Considerations

Cost can also be a deciding factor:

Generally, metal paint is more cost-effective, particularly for larger surfaces or industrial applications where the primary goal is protection. The long-term benefits of reduced maintenance and longer life span often outweigh the initial cost.

Metallic Paint is generally more expensive due to the reflective particles (such as aluminum or mica) used in its formula. It also often requires a clear topcoat to enhance durability, adding to the overall cost. However, the visual impact it delivers can justify the expense for high-end or design-centric projects.

Practical Examples to Help Decide.

- Scenario 1: You are looking to repaint an exterior metal staircase that is exposed to the elements year-round. In this case, metal paint is the best choice due to its superior durability, resistance to weather, and low maintenance needs.

- Scenario 2: You want to create a glamorous, reflective accent wall in your living room to match a contemporary décor style. Here, metallic paint would be more appropriate, offering the shiny, visually appealing finish that catches light beautifully.

Choosing between metallic paint and metal paint comes down to understanding your project’s specific needs. For protection and longevity on metal surfaces, metal paint is your best bet. If you are looking for a decorative finish that dazzles and draws attention, metallic paint will provide the impact you desire. By considering factors like the application surface, environment, desired effect, and maintenance, you can confidently select the paint that meets both your functional and aesthetic requirements.

Which types of polymer paint are suitable for metal?

When it comes to painting metal surfaces, choosing the right type of paint is crucial to ensure durability, protection, and the desired finish. Different types of polymer-based paints offer various benefits, such as resistance to corrosion, weatherability, and aesthetic appeal. Each type of paint has its own set of properties tailored for specific applications. This guide will provide a detailed overview of various polymer paint types that are suitable for metal surfaces, helping you make an informed decision for your next project. Types of Polymer Paint Suitable for Metal

- Water-Based Paints

Water-based paints, also known as latex or acrylic paints, are formulated with water as the solvent, making them environmentally friendly and low in volatile organic compounds (VOCs). They are suitable for interior metal surfaces where minimal exposure to harsh elements is expected. Water-based paints dry quickly, have low odor, and provide a smooth finish, but they may not offer the same level of durability and corrosion resistance as other types of polymer paints. - Polyurethane Paints

Polyurethane paints are highly versatile and durable, providing excellent resistance to abrasion, chemicals, and UV radiation. These paints are ideal for both indoor and outdoor metal surfaces, including machinery, vehicles, and architectural elements. Polyurethane coatings create a hard, glossy finish that is resistant to scratches and fading, making them perfect for surfaces that require a high level of durability and aesthetic appeal. Their flexibility also allows them to expand and contract with the metal, preventing cracking and peeling over time.

- Alkyd (Oil-Based) Paints

Alkyd paints, commonly referred to as oil-based paints, are known for their durability and strong adhesion to metal surfaces. They are highly resistant to wear and tear, making them ideal for metal surfaces exposed to heavy use or harsh weather conditions. Alkyd paints offer a glossy finish and are commonly used for outdoor metal structures like fences, railings, and gates. However, they tend to release higher levels of VOCs compared to water-based options, which may require additional ventilation during application. - Acrylic Paints

Acrylic paints are water-based but offer greater durability and weather resistance than standard water-based paints. They are suitable for both interior and exterior metal surfaces and provide excellent color retention over time. Acrylic paints dry quickly and are less prone to fading and yellowing, making them ideal for decorative metal surfaces. They are also resistant to chipping and cracking, offering a balance between performance and environmental friendliness. - Epoxy Paints

Epoxy paints are renowned for their exceptional adhesion, chemical resistance, and durability, making them one of the best choices for industrial metal surfaces. These paints form a hard, protective layer that is resistant to abrasion, moisture, and many chemicals, which is why they are often used in environments such as factories, warehouses, and marine settings. Epoxy coatings provide a long-lasting, tough finish that can withstand heavy mechanical stress, but they require careful preparation and proper application techniques to achieve optimal results. - Chlorinated Rubber Paints

Chlorinated rubber paints are formulated with synthetic rubber polymers that provide excellent resistance to water, chemicals, and UV light. These paints are highly flexible and durable, making them suitable for metal surfaces exposed to harsh environments, such as swimming pools, tanks, and marine equipment. Chlorinated rubber coatings are known for their ability to adhere well to metal surfaces, offering long-term protection against corrosion and weathering. - Zinc-Rich Paints

Zinc-rich paints are a specialized type of coating designed to provide sacrificial protection to metal surfaces, particularly steel. These paints contain a high concentration of zinc dust, which offers cathodic protection by corroding preferentially to the metal substrate. Zinc-rich coatings are ideal for structures exposed to aggressive environments, such as bridges, pipelines, and marine equipment. They are often used as a primer in combination with other types of polymer paints to enhance overall corrosion resistance.

| Comparative Table of Polymer Paint Types for Metal | |||||

|---|---|---|---|---|---|

| Paint Type | Main Purpose | Key Characteristics | Suitable Environments | Advantages | Disadvantages |

| Water-Based | Indoor Use | Low VOC, quick drying | Interior surfaces | Environmentally friendly | Limited durability |

| Polyurethane | High Durability | Resistant to UV, chemicals | Outdoor surfaces, vehicles | High durability, glossy finish | Higher cost |

| Alkyd (Oil-Based) | Outdoor Use | Strong adhesion, glossy finish | Fences, railings | Long-lasting, good weather resistance | High VOC, longer drying time |

| Acrylic | Decorative | Quick drying, low odor | Interior and exterior surfaces | Good color retention, less yellowing | Less durable than epoxy |

| Epoxy | Industrial Use | Highly durable, chemical resistant | Factories, marine settings | Long-lasting, tough finish | Requires proper surface preparation |

| Chlorinated Rubber | Water Resistance | Flexible, UV resistant | Swimming pools, marine equipment | Excellent weather resistance | Limited color choices |

| Zinc-Rich | Corrosion Protection | High zinc content | Bridges, pipelines | Superior corrosion resistance | Requires a topcoat |

Selecting the right type of polymer paint for metal surfaces depends on various factors, including the application environment, desired durability, aesthetic appeal, and specific performance requirements. By understanding the different types of polymer paints and their unique properties, you can make an informed choice that meets your project’s needs. For a more comprehensive guide on different types of polymer coatings, check out our detailed blog post.

By differentiating between Metallic Paint and Metal Paint, you can make an informed decision about which coating is best for your specific needs. From their unique properties to the best applications and polymer coatings for metal surfaces, understanding the options will guide you to the best choice, whether you need a coating that provides protection, beauty, or both. For those looking to find the perfect supplier, on-site painting contractor, or batch spraying factory tailored to your requirements, utilize the comprehensive search capabilities on coatingsdirectory.com to find exactly the product or service you need and connect with a Metallic Paint and Metal Paint expert.

How long does spray paint take to dry on metal?

Spray paint usually dries on metal in about 10-30 minutes to the touch, but full curing can take up to 24 hours. It depends on factors like the type of paint, humidity, and temperature.

To speed up the drying process, use thin, even coats and make sure the surface is clean and smooth. Oil-based spray paints tend to dry slower than acrylic-based ones, and cooler, more humid conditions can extend drying times. Always check the manufacturer’s recommendations for the best results.

Can you paint metal with acrylic?

Yes, you can paint metal with acrylic, but it requires proper surface preparation. Acrylic paint can adhere well to metal when a suitable primer is used.

Before applying acrylic paint, clean the metal surface thoroughly to remove any rust, dirt, or grease. Using a primer specifically designed for metal surfaces helps the acrylic paint bond better, offering a smooth and long-lasting finish. Acrylic paints are ideal for indoor metal objects, like furniture or decorative pieces, but may require a clear sealant to protect against wear and moisture.

Can metallic paint be used on metal surfaces?

Of course, metallic paint can be used on metal surfaces! It’s perfect for adding a shiny, reflective effect that enhances the beauty of metal objects.

When applying metallic paint to metal, the key is to properly prepare the surface by cleaning and priming. Metallic paint comes in oil-based and water-based formulas, both of which provide a durable finish for interior and exterior applications. Make sure to apply an even coat and allow ample drying time between coats for the best results. In addition to metal surfaces, metallic paint can also be applied to concrete, masonry, plastic, siding, wood, plaster, stucco, and previously painted surfaces.

Are there specific brands recommended for metallic or metal paint?

Yes, some brands are known for their high-quality metallic and metal paints. Popular choices include Rust-Oleum, Krylon, and Valspar, which offer durable and easy-to-apply options.

Rust-Oleum is known for its rust-resistant properties, making it ideal for outdoor metal surfaces. Krylon provides a range of colors with fast-drying features, while Valspar offers a variety of finishes and good coverage. Depending on your project’s specific needs, any of these brands can deliver reliable performance.You can also use the coatingsdirectory platform to filter out the metallic paint brands that are right for you.

What is the lifespan of metallic paint vs. metal paint?

Metallic paint generally lasts 5-10 years on surfaces, depending on exposure to elements, while metal paint (especially rust-resistant formulas) can last even longer, around 10-15 years.

The longevity of metallic or metal paint depends on factors such as environmental conditions, preparation quality, and maintenance. Metallic paints may require more frequent touch-ups due to their finish’s wear, while metal paints, particularly those with protective properties, are designed to endure tough conditions longer. Regular maintenance, like cleaning and protective coatings, can help extend the lifespan of both types.